The market prospects for unsealed plastic layer pads with rounded corners appear promising. As the logistics and packaging industries continue to expand, there is a growing demand for versatile, reliable, and efficient packaging solutions. These pads offer enhanced cushioning and stability, making them ideal for protecting delicate items during shipping and storage. Additionally, their design allows for easy customization and branding opportunities, which can attract businesses looking to elevate their product presentation. With increasing emphasis on sustainability, there is also potential for eco-friendly variations of these pads to gain traction in the market. Overall, the combination of functionality, versatility, and potential for customization positions unsealed plastic layer pads with rounded corners for a positive outlook in the evolving packaging landscape.

Unsealed Plastic Layer Pads With Rounded Corners. Advantages

Unsealed Plastic Layer Pads With Rounded Corners possess several notable advantages. Here are some of them:

Enhanced Cushioning Performance

- The rounded corners and unique design help distribute pressure more evenly when the pads are used for cushioning during transportation or storage. This can effectively reduce the risk of damage to delicate items, providing better protection compared to traditional flat – cornered pads.

- They can absorb shocks and vibrations well, which is particularly important for products that are sensitive to impacts, such as electronic devices, glassware, and precision instruments.

Improved Stability

- The shape and structure of these pads with rounded corners offer better stability when stacking or arranging items. They are less likely to shift or slide around, ensuring that the products remain in place and reducing the chances of accidents or damage during handling.

- This is especially beneficial in industries such as warehousing and logistics, where efficient and stable packaging is crucial for smooth operations.

Versatility in Applications

- Unsealed plastic layer pads with rounded corners can be used in a wide range of industries and applications. From food and beverage packaging to industrial product protection, their adaptability makes them a popular choice.

- They can accommodate various product sizes and shapes, providing a flexible packaging solution that can meet the diverse needs of different businesses.

Easy to Handle and Store

- The unsealed design allows for quick and easy placement and removal of items. This not only saves time but also reduces the labor cost associated with packaging and unpackaging processes.

- When not in use, these pads can be conveniently stored due to their space – efficient design. They can be stacked or nested together, taking up minimal storage space.

Cost – Effectiveness

- They are often more affordable compared to some other specialized packaging materials while still offering excellent performance. This makes them an economical choice for businesses looking to balance cost and quality in their packaging operations.

- The durability of the plastic material ensures that the pads can be reused multiple times, further enhancing their cost – effectiveness.

Customization Options

- These pads can be easily customized in terms of size, thickness, and color according to specific requirements. This allows businesses to create packaging solutions that align with their brand identity and product characteristics.

- Custom printing, such as adding company logos or product information, is also possible on the surface of the pads, providing additional marketing and branding opportunities.

In summary, unsealed plastic layer pads with rounded corners offer enhanced cushioning, improved stability, versatility, ease of handling, cost – effectiveness, and customization options, making them a valuable packaging solution for various industries.

Product Details

Sure! Here is a summary of the relevant parameters of unsealed plastic layer pads with rounded corners in English table form:

| Parameter | Description |

|---|---|

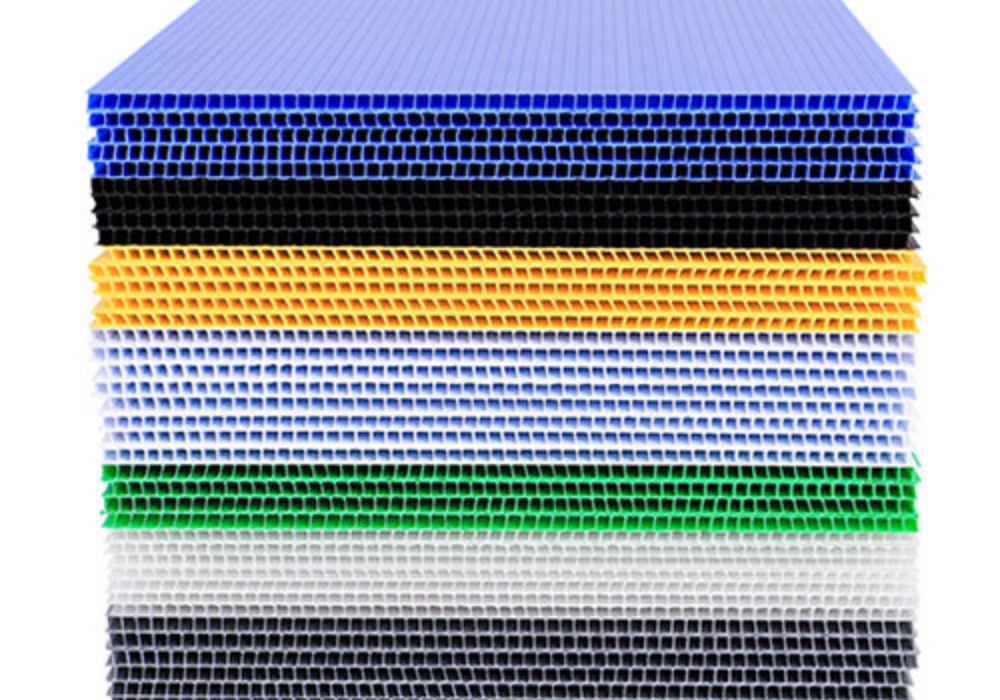

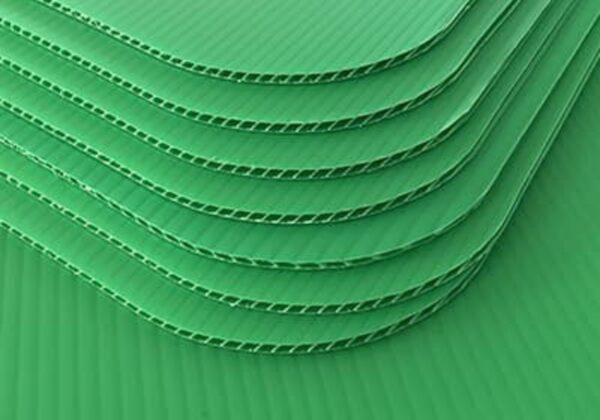

| Material | High – quality polypropylene (PP) or polyethylene (PE) plastic, which is durable, lightweight, and recyclable. |

| Size | Available in various standard sizes to accommodate different product dimensions, such as 12inches× 12inches (305mm × 305mm), 18inches× 24inches (457mm × 610mm), etc. Custom sizes can also be produced according to specific requirements. |

| Thickness | Ranges from a thin gauge suitable for light – weight items to a thicker gauge for heavier and more fragile products. Common thicknesses include 0.5mm, 1mm, 2mm, etc. |

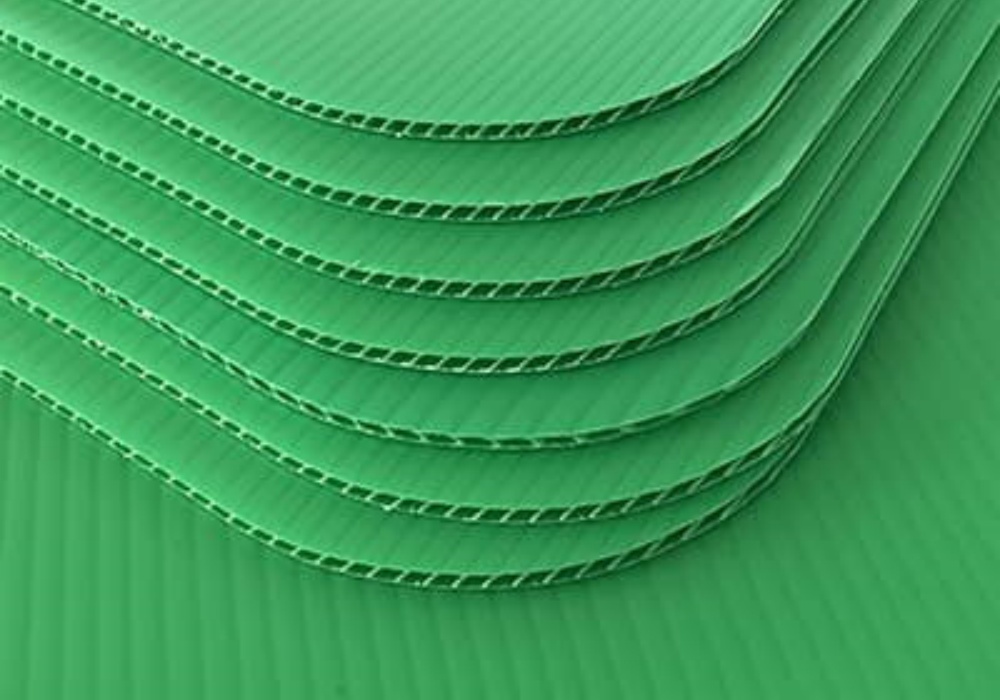

| Color | Typically comes in translucent or opaque options, with standard colors like white, black, blue, green, yellow, etc. Custom colors can also be made to meet specific branding or coding needs. |

| Surface Texturing | May have a smooth surface or a textured surface. The textured surface can provide better grip and stability for the products, reducing the risk of slippage during handling and transportation. |

| Rounded Corner Radius | The radius of the rounded corners is designed to be safe and effective in protecting products from edge – related damage. It is usually within a range that ensures proper cushioning and stability. |

| Load – Bearing Capacity | Depends on the size, thickness, and material of the pad. It can support varying weights, from light objects like electronic accessories to heavier items such as machinery parts or small appliances. |

| Temperature Resistance | Can withstand a certain temperature range, generally suitable for use in environments from – 20℃ to 80℃. However, this may vary depending on the specific material and formulation used. |

| Moisture Resistance | Resistant to moisture and water – based solutions, making them suitable for packaging and protecting products in humid environments or during wet transportation conditions. |

| Eco – Friendliness | As they are made of plastic, they are recyclable after use. Some manufacturers also offer environmentally – friendly options, such as using recycled materials or producing biodegradable plastic pads. |

The above table summarizes the basic parameters of unsealed plastic layer pads with rounded corners, and the specific values may vary according to different manufacturers and product designs.

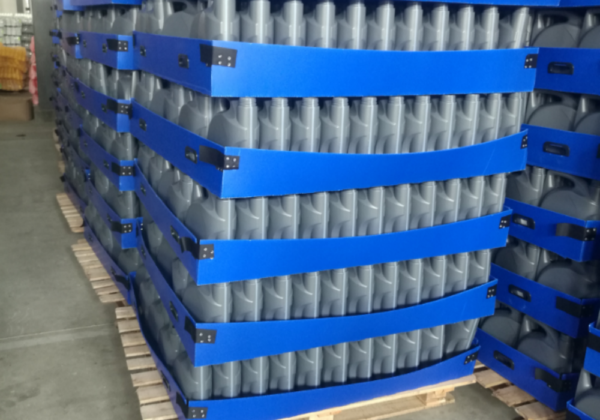

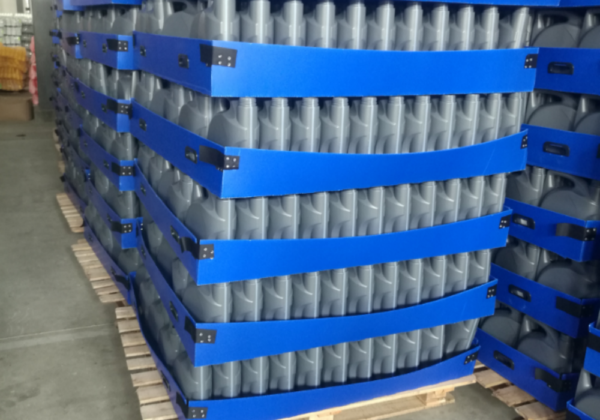

Product Gallery

Unsealed Plastic Layer Pads With Rounded Corners. What is the price range

The price range of unsealed plastic layer pads with rounded corners can vary depending on several factors. Here is a general overview of the price range:

1. Material Quality

- Standard Polypropylene (PP) or Polyethylene (PE): These are the most common materials used. The prices for basic quality PP or PE pads usually range from a few cents to several dollars per pad, depending on the size and thickness.

- High – Quality or Specialty Plastics: For applications requiring higher durability, resistance to chemicals, or other specific properties, the price can be higher. These specialty plastic pads may cost several dollars to over ten dollars per pad, depending on the material and specifications.

2. Size and Thickness

- Small Sizes (e.g., 12 inch × 12 inch or smaller): These are relatively inexpensive and may cost from 0.10to0.10to0.50 each for thinner gauges (0.5 – 1mm). As the size increases, the price also goes up.

- Large Sizes (e.g., 18 inch × 24 inch or larger): For standard materials and larger sizes, the price per pad can range from 0.50to0.50to2 or more, depending on the thickness and quality.

- Thicker Gauges (e.g., 2mm – 5mm): Thicker pads provide better cushioning but are more expensive. They can cost from 1to1to5 or more per pad for larger sizes.

3. Order Quantity

- Small Quantities: If you purchase a small number of pads (less than 100 pieces), the unit price will generally be higher, ranging from 1to1to10 or more per pad, depending on the size and material.

- Bulk Orders: For larger orders (hundreds or thousands of pieces), the price per pad can be significantly lower due to volume discounts. Bulk prices can start from as little as 0.05to0.05to0.50 per pad for standard sizes and materials.

4. Customization

- Custom Sizes and Shapes: If you require non-standard sizes or custom – shaped pads, the price will be higher due to the additional manufacturing costs. The exact price will depend on the complexity and quantity of the custom order.

- Custom Printing: Adding custom printing, such as company logos, product information, or barcodes, will increase the price. The cost depends on the printing method and the number of colors used. Simple printing may add a few cents to a few dollars per pad, while more complex printing can increase the price by $1 or more per pad.

5. Supplier and Location

- Domestic Suppliers: Purchasing from local suppliers in your country may have lower transportation costs but could be more expensive due to higher production and labor costs. Prices from domestic suppliers can vary widely, with some charging premium prices for similar products.

- International Suppliers: Sourcing from international suppliers, especially in regions with lower production costs, can result in lower prices. However, you need to consider additional costs such as shipping, import duties, and potential currency exchange rate fluctuations. International prices may range from a fraction of a cent to a few dollars per pad, depending on the supplier and order quantity.

In general, for standard unsealed plastic layer pads with rounded corners made of polypropylene or polyethylene, the price range for small – to medium – sized pads (up to 18 inch × 24 inch) and thicknesses up to 2mm is approximately 0.10to0.10to2 per pad in bulk quantities. For larger pads, thicker materials, or custom – made options, the price can go up to $5 or more per pad. It’s always advisable to request quotes from multiple suppliers to get the best price for your specific requirements.

Unsealed Plastic Layer Pads With Rounded Corners

certified by

Make the smart choice for your packaging needs and elevate your product presentation with our Unsealed Plastic Layer Pads With Rounded Corners – because every detail matters when it comes to delivering excellence!

Specifications

Thickness: a few millimeters to several tens of millimeters

Size: Customized

Color: Customized

Hardness: determined by its material and design

Density: about 0.91g/cm³

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon