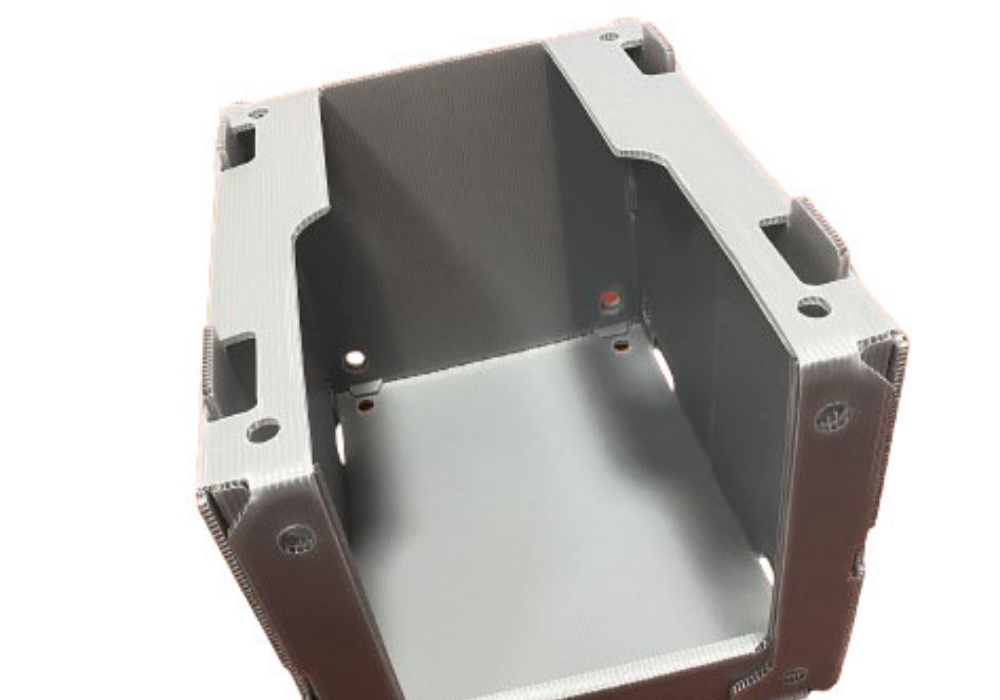

The manufacturing process of Grey Plastic Picking Boxes involves several key steps. First, high-quality plastic materials like HDPE or PP are selected for their strength and durability. These materials are then heated and injected into custom-designed molds under high temperature and pressure, taking shape as the picking boxes. The molds are designed with precision to ensure product consistency and accuracy. After the boxes are molded, they undergo post-processing procedures such as deburring, polishing, and cleaning to enhance their overall quality and appearance. Special surface treatments may also be applied to meet specific application requirements. Throughout the production process, strict quality control and testing are conducted to ensure that each picking box meets high standards. Finally, the boxes are packaged and prepared for shipment according to customer requirements. In summary, the manufacturing process of Grey Plastic Picking Boxes is a complex and finely tuned procedure that combines advanced production equipment and techniques with stringent quality control measures to produce durable, high-quality, and visually appealing plastic picking boxes.

What is the manufacturing process for Grey Plastic Picking Boxes

The manufacturing process of Grey Plastic Picking Boxes mainly consists of the following key steps:

Material Selection: High-quality plastic raw materials such as High-Density Polyethylene (HDPE) or Polypropylene (PP) are chosen for their strength, durability, and impact resistance, making them suitable for producing durable picking boxes.

Injection Molding: The selected plastic raw materials are heated to a molten state and then injected into pre-designed molds. Under high temperature and pressure, the plastic cools and solidifies inside the mold, forming the basic shape of the picking boxes. Injection molding ensures product consistency and accuracy while improving production efficiency.

Mold Design and Manufacturing: Molds are customized according to customer needs and product design requirements. Mold design considers factors such as product shape, size, structure, and surface texture. High-precision processing equipment and techniques are used during manufacturing to ensure the quality and accuracy of the molds.

Post-Processing Procedures: Steps include deburring, polishing, cleaning, etc., to improve the overall quality and appearance of the products. Additionally, special surface treatments such as anti-slip and anti-static treatments may be performed to meet specific application needs.

Quality Inspection and Control: Throughout the production process, strict quality control and testing are conducted at every stage. From the inspection of raw materials to the factory testing of finished products, every picking box is ensured to meet high-quality standards.

Packaging and Transportation: After completing all manufacturing and testing procedures, the picking boxes are properly packaged to protect them during transportation and storage. Shipping is then arranged according to customer needs.

In summary, the manufacturing process of Grey Plastic Picking Boxes is a complex and detailed procedure that covers multiple aspects from material selection to the final product. Through advanced production equipment and techniques, combined with a strict quality control system, high-quality, durable, and aesthetically pleasing plastic picking boxes can be produced.

Product Details

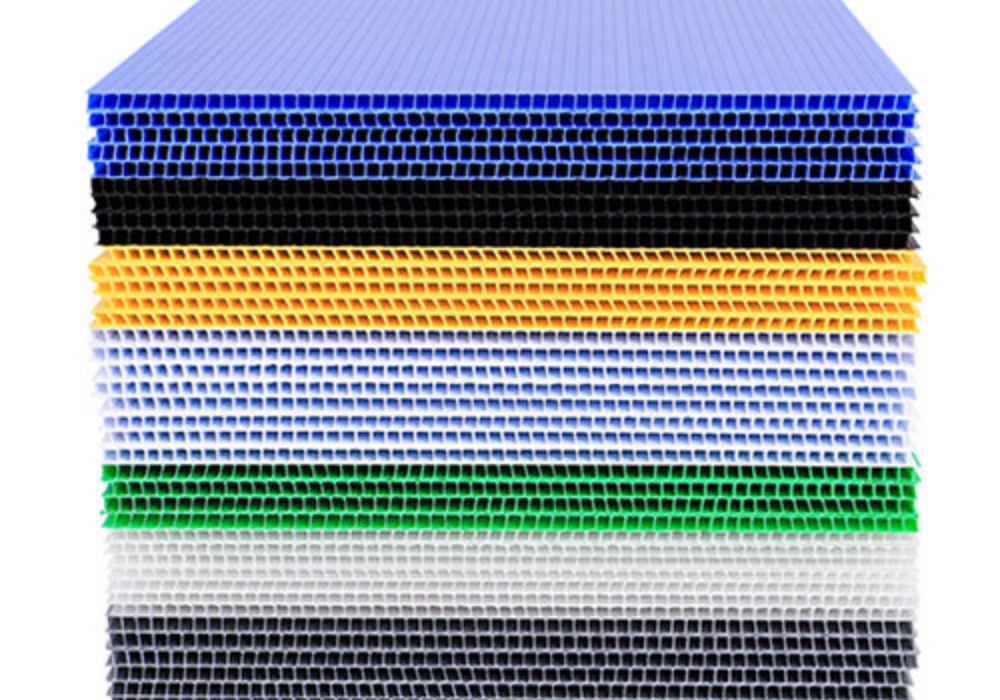

Customized Correx Pick Bins are highly versatile and customizable storage solutions designed to meet the specific needs of various industries. Here is a table summarizing their key parameters:

| Parameter | Description |

|---|---|

| Material | High-density polypropylene (HDPE) or polypropylene (PP) |

| Thickness | 2mm to 15mm |

| Color Options | Customizable, typically including but not limited to blue, black, white, yellow, red, green, grey, etc. |

| Shape | Rectangular, square, round, or any custom shape as per requirement |

| Size | Custom dimensions based on specific needs, with no standard size limitation |

| Load Capacity | Dependent on the thickness and design, generally ranging from light to heavy loads |

| Surface Finish | Smooth or textured, can be printed or labeled easily |

| Resistance | Waterproof, moisture-resistant, and resistant to mold and mildew |

| Eco-Friendliness | Made from recyclable materials, reducing environmental impact |

| Stacking Feature | Designed to stack stably for efficient space utilization in warehouses |

| Printing Methods | Screen printing, UV coating, varnishing, glossy lamination, matte lamination, etc. |

| Usage | Widely used in logistics, e-commerce, food processing, cosmetics, pharmaceuticals, automotive, and other industries for picking and storing goods |

| Delivery Time | Typically 7-15 working days after receiving payment |

| MOQ (Minimum Order Quantity) | Varies by supplier, generally around 100 pieces or more |

| Certification | ISO9001, SGS, RoHS, and others, depending on the manufacturer’s compliance |

These parameters make Customized Correx Pick Bins suitable for a wide range of applications where durability, customization, and efficient space management are crucial.

Product Gallery

What is the market outlook for Grey Plastic Picking Boxes

The market prospects of Grey Plastic Picking Boxes are broad, and the following is a specific analysis:

Increasing Demand in the Manufacturing Industry: With the continuous development of the global manufacturing industry, especially the expanding production scale of industries such as electronics, automobiles, and machinery, there are higher and higher requirements for the refined management and efficient delivery of components. Grey Plastic Picking Boxes can provide good solutions for these industries, helping to improve production efficiency and product quality. Therefore, they have good application prospects in the manufacturing industry. For example, in the electronics products manufacturing, they can be used for storing and transporting small electronic components; in the auto parts production, they can serve as turnover containers for parts.

Driving Force from the Logistics and Warehousing Industry: The vigorous development of e-commerce has led to the rapid expansion of the logistics and warehousing industry. Grey Plastic Picking Boxes can be used in distribution centers and warehouses for the sorting, packaging, and temporary storage of goods. Their durability, ease of cleaning, and identifiability meet the high-intensity use requirements in logistics operations, helping to improve the efficiency and accuracy of logistics operations and reduce the damage rate of goods. In addition, with the development of cold chain logistics, there is also an increasing demand for plastic picking boxes that can be used in low-temperature environments. Gray plastic picking boxes can meet this demand by adding special thermal insulation materials or using appropriate plastic materials.

Expanding Applications in the Food and Pharmaceutical Industries: In the food and pharmaceutical industries, there are extremely high requirements for hygiene and safety standards. Grey Plastic Picking Boxes can be made from plastic raw materials that meet food safety standards and treated with sterilization technology to ensure that they do not affect the quality of food and drugs when coming into contact with them. At the same time, their corrosion resistance and ease of cleaning also make them ideal picking and packaging tools for these two industries. They can be used in the processing, packaging, and distribution of food as well as in the production and storage processes of drugs for item picking.

Opportunities Brought by Enhanced Environmental Awareness: Consumers’ attention to environmentally friendly products is continuously increasing, and more and more enterprises are beginning to focus on the construction of green supply chains. Compared with traditional paper and wooden packaging materials, gray plastic picking boxes have the advantage of recyclability and meet environmental concepts. If a sound recycling system can be established to recycle and reprocess the used picking boxes, it can not only reduce resource waste but also reduce enterprises’ packaging costs, thus making them more competitive in the market.

Trend of Customized Services: Different industries and enterprises have different needs for the size, shape, and partition mode of picking boxes. In the future, Grey Plastic Picking Boxes manufacturers that can provide customized services will be more welcomed in the market. For example, according to the specific product size and packaging requirements of customers, customizing picking boxes of special specifications or adding special signs and label slots on the picking boxes to meet the personalized needs of customers.

Technological Innovations Boost Development: With the continuous progress of technology, the application of technologies such as the Internet of Things and automation technology in the field of picking boxes will bring more functions and values to Grey Plastic Picking Boxes. For example, by installing intelligent sensors and tracking devices on the picking boxes, it is possible to monitor the location and status of goods in real-time, realizing intelligent inventory management and logistics scheduling; in combination with automated equipment such as automatic picking robots, the efficiency and accuracy of picking can be further improved, which will further promote the development of the industry.

In summary, Grey Plastic Picking Boxes have good market prospects in multiple industries due to their various advantages. Although they also face some challenges, overall, as long as enterprises can seize market demands, continuously improve product quality and innovation ability, and actively respond to various challenges, they can occupy a place in this market and achieve sustainable development.

Grey Plastic Picking Boxes

certified by

Upgrade your warehouse organization with our Grey Plastic Picking Boxes – where practicality meets style for efficient and sleek storage solutions.

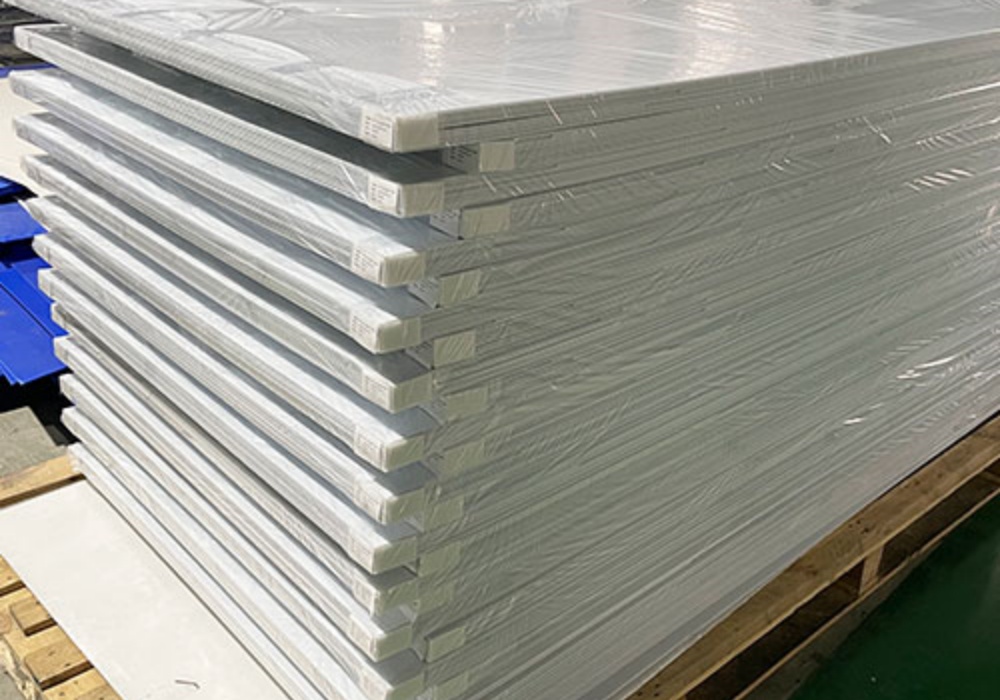

Specifications

Thickness: 2-12mm

Size: Customized

Color: Customized

Hardness: determined by its material and design

Density: 0.91-0.96 grams per cubic centimeter

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon