The price range for custom corrugated plastic boxes for ginger can vary greatly depending on the level of customization and order quantity. For simple designs with standard sizes, prices typically start at around 0.50perboxforbulkorders.Moreintricatecustomizations,suchasspecificbranding,colors,oradditionalfeatures,canincreasethecosttoarangeof0.50perboxforbulkorders.Moreintricatecustomizations,suchasspecificbranding,colors,oradditionalfeatures,canincreasethecosttoarangeof1 to $3 per box. The final price may also be influenced by the order quantity and any extra processing requirements. To get a precise quotation tailored to your needs, please contact our sales team directly.

custom corrugated plastic boxes for Ginger are most popular in those industries

Custom corrugated plastic boxes for Ginger are most popular in the following industries:

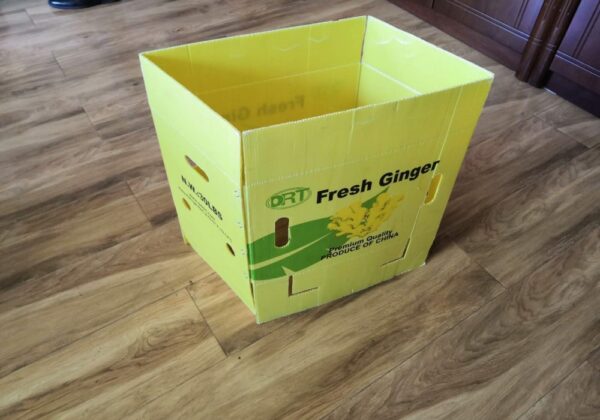

Food Packaging and Processing: These boxes are widely used for packaging and transporting fresh ginger and other root vegetables, ensuring their safe and secure delivery while maintaining ventilation to keep the produce fresh.

Agriculture and Farming: Farmers and agricultural workers prefer these boxes for collecting, handling, and transporting ginger from fields to markets or processing units, as they provide durability and protection against external damage.

Retail and Supermarkets: Retailers use custom corrugated plastic boxes to display and sell ginger in stores. The attractive design and branding options help in attracting customers and enhancing the product’s presentation on the shelves.

Export and Import Trade: In the international trade of agricultural products, these boxes are essential for packaging ginger during transportation across borders, ensuring that the ginger remains intact and of high quality upon arrival at its destination.

Horticulture and Garden Centers: Such boxes are also popular among nurseries and garden centers for packaging and selling ginger plants or rhizomes, providing a sturdy and professional packaging solution.

Product Details

Sure! Here is a parameter table for corrugated polypropylene boxes used for fruit packaging:

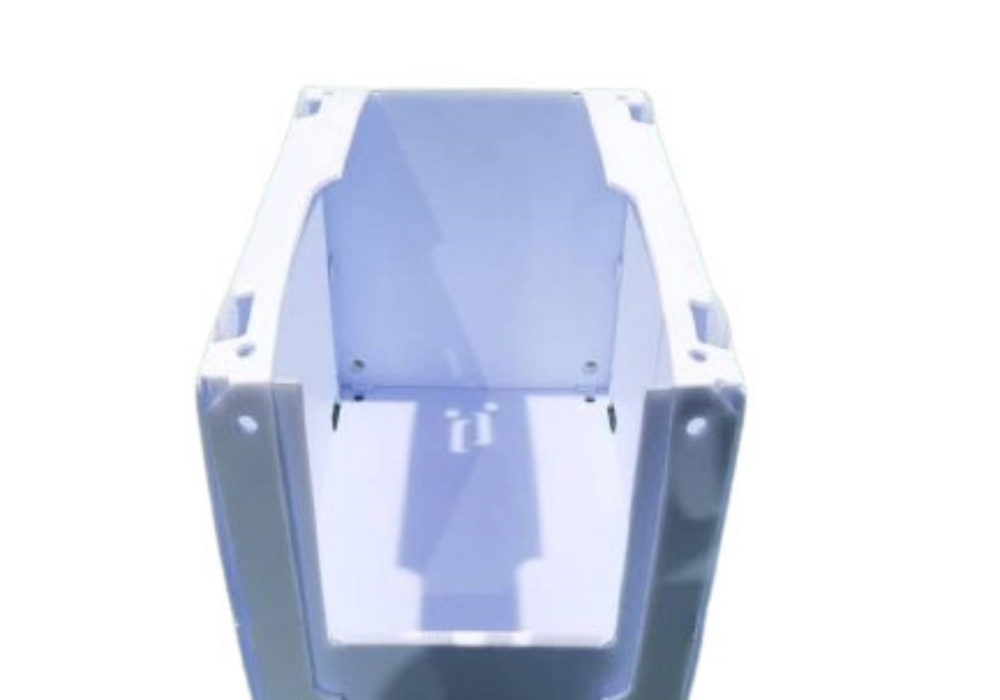

| Parameter | Details |

|---|---|

| Material | High-quality corrugated polypropylene (PP) |

| Size | Variable (common sizes include 400x300x250mm, 500x400x300mm, etc. Can be customized based on requirements) |

| Thickness | Ranges from 2mm to 5mm (can be adjusted according to the level of protection needed) |

| Weight capacity | Generally, can hold up to 15-20kg of fruit safely |

| Color | Usually available in natural translucent, white, blue, green, yellow, etc. (color options may vary by supplier) |

| Ventilation | Designed with ventilation holes or slats to ensure proper air circulation |

| Stacking strength | Capable of supporting stacking of 3-4 boxes high without deformation |

| Temperature resistance | Withstands temperatures from -10°C to +70°C, suitable for various environmental conditions during storage and transportation |

| Moisture resistance | Excellent resistance to moisture, preventing water damage and mold growth |

| Customization options | Can be customized with logos, branding, size, color, and labeling as per customer’s requirements |

| Reusability | Durable and reusable, designed for multiple trips and long-term use to reduce waste and cost |

Product Gallery

custom corrugated plastic boxes for Ginger What is the manufacturing process

The manufacturing process of custom corrugated plastic boxes for ginger is detailed and precise to ensure the final product meets the required standards for durability, protection, and aesthetics. Here is a step-by-step overview:

Material Selection: The process begins with the selection of high-quality polypropylene (PP) sheets, which are known for their strength, lightweight properties, and resistance to moisture and chemicals. These materials are ideal for packaging products like ginger that need to be kept fresh during transportation and storage.

Design and Customization: Next, the design phase involves creating custom dimensions and shapes based on the client’s specifications. This may include incorporating features such as ventilation holes to maintain airflow around the ginger, ensuring its freshness. The design is often created using computer-aided design (CAD) software, allowing for precise measurements and adjustments before moving to production.

Cutting and Shaping: Once the design is finalized, the selected PP sheets are cut into the desired shapes using die-cutting machines or CNC routers. This step ensures that each piece fits together perfectly to form the corrugated structure of the box.

Corrugation Process: The unique corrugated pattern is then formed by passing the flat PP sheets through a corrugating machine. This machine presses the material into a wave-like shape, which provides additional strength and cushioning to the box. The height and frequency of the corrugations can be adjusted according to the intended use and load requirements.

Assembly and Gluing: After corrugation, the individual components of the box are assembled and glued together using specialized adhesives that are safe for food contact. This step requires careful alignment and pressing to ensure a sturdy and seamless construction.

Printing and Finishing: If required, the boxes undergo printing and finishing processes. This can include adding brand logos, product information, or decorative elements through methods like silk screen printing, heat transfer printing, or digital printing. The printed designs are typically protected with a layer of clear coating to enhance durability and appearance.

Quality Control and Inspection: Before being packaged for shipping, each box undergoes rigorous quality control checks. This includes inspecting the structural integrity, print quality, and overall appearance to ensure it meets industry standards and customer expectations.

Packaging and Shipping: Finally, the completed boxes are carefully packed and prepared for shipment. They are often stacked on pallets and wrapped in protective films to prevent damage during transit. Depending on the order size and destination, they may be shipped via commercial express services, air freight, or sea freight.

custom corrugated plastic boxes for Ginger

certified by

Premium Protection, Natural Freshness – Custom Corrugated Plastic Boxes for Ginger

Specifications

Place of Origin: China (Mainland)

Material: PP

Color: Black/White/Gey/Blue/Custom

Size: Can be customized

OEM/ ODM: Accept

MOQ: 500pcs

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon