The manufacturing process of a corrugated plastic trash bin begins with the selection of high-quality polypropylene (PP) or high-density polyethylene (HDPE) materials. These raw materials are mixed with colorants and auxiliary agents, and then melted in an extruder. The melted material is extruded into flat sheets through a die head and cooled to solidify. Next, the flat sheets are printed, coated with protective layers, and cut into the appropriate shapes using a die-cutting machine or laser cutting machine. Finally, the various parts are assembled and connected by welding or adhesive methods to form the corrugated plastic trash bin. The product is inspected for quality, packaged, and prepared for shipment.

Corrugated plastic trash bin market outlook

The following is an analysis of the market prospects for corrugated plastic trash bins:

Positive Factors

- Driven by Environmental Awareness: As global awareness of environmental protection continues to increase, people are more inclined to choose sustainable products. Corrugated plastic trash bins are made of recyclable materials and can be reused themselves, in line with the current trend of environmental protection. In regions and consumer groups with strong environmental awareness, market demand is expected to continue to grow.

- Advantages of Durability and Reliability: These trash bins have high strength and durability, able to withstand greater weight and external impact, and are not easily damaged or deformed. Whether in homes, commercial places, or industrial environments, their reliable performance can meet the needs of long-term use, reducing the frequency of replacement, and thus在一定程度上 reducing the overall cost.

- Diverse Application Scenarios: Corrugated plastic trash bins are suitable for various scenarios, such as household waste sorting, office file storage, school classroom storage, hospital waste treatment, outdoor activities, etc. Different specifications and models of products can meet the needs of different users, providing a broad space for market expansion.

- Increasing Demand for Customization: Consumers are increasingly demanding personalized products. Corrugated plastic trash bins can be customized according to the specific needs of customers, including size, color, printed patterns, etc. This enables the products to meet the promotional and decorative requirements of specific places or brands, increasing the added value and market competitiveness of the products.

- Driving Force from the Development of E-commerce and Logistics: The popularity of online shopping has made product sales channels more extensive. Consumers can conveniently purchase corrugated plastic trash bins on e-commerce platforms and have them quickly delivered to their homes. Meanwhile, the improvement of logistics efficiency also helps reduce transportation costs and time costs, further promoting product sales and market expansion.

Challenge Factors

- Intense Competition: There are multiple types of trash bin products made of different materials in the market, such as plastic trash bins, metal trash bins, paper trash bins, etc., which form competition in different price ranges and performance characteristics. In addition, the number of enterprises in the corrugated plastic trash bin industry is also increasing, and market competition is becoming increasingly fierce. Enterprises need to continuously improve product quality, reduce costs, innovate in design, and strengthen brand building to occupy a place in the market.

- Fluctuation in Raw Material Prices: The main raw materials of corrugated plastic trash bins are polypropylene (PP) and other plastics, and their prices are greatly affected by factors such as oil prices and market supply and demand relationships. Fluctuations in raw material prices may increase the production costs of enterprises and compress profit spaces. If enterprises cannot effectively respond, it may affect the market pricing and sales strategies of products.

- Limited Consumer Awareness: Although corrugated plastic trash bins have certain advantages, some consumers do not have a deep understanding of their performance and characteristics and may be more inclined to choose traditional materials trash bins. Therefore, enterprises need to strengthen market promotion and publicity to improve consumers’ awareness and acceptance of corrugated plastic trash bins.

In summary, the corrugated plastic trash bin market has broad prospects, but it also faces some challenges. Enterprises need to give full play to the advantages of products, actively respond to various challenges, continuously innovate and upgrade to adapt to market changes and developments, and achieve sustainable development.

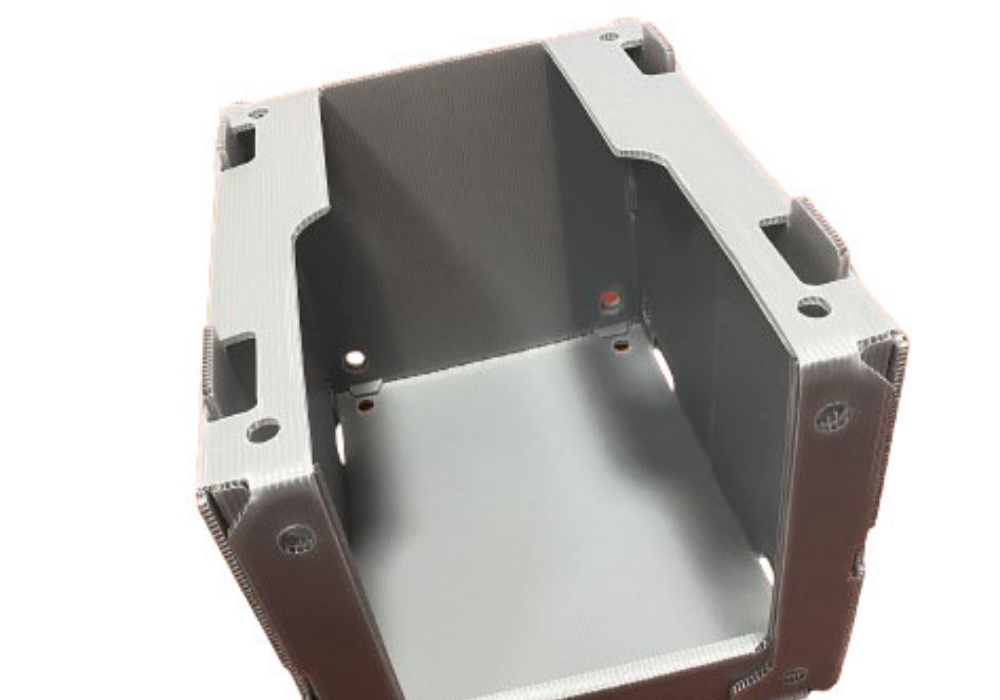

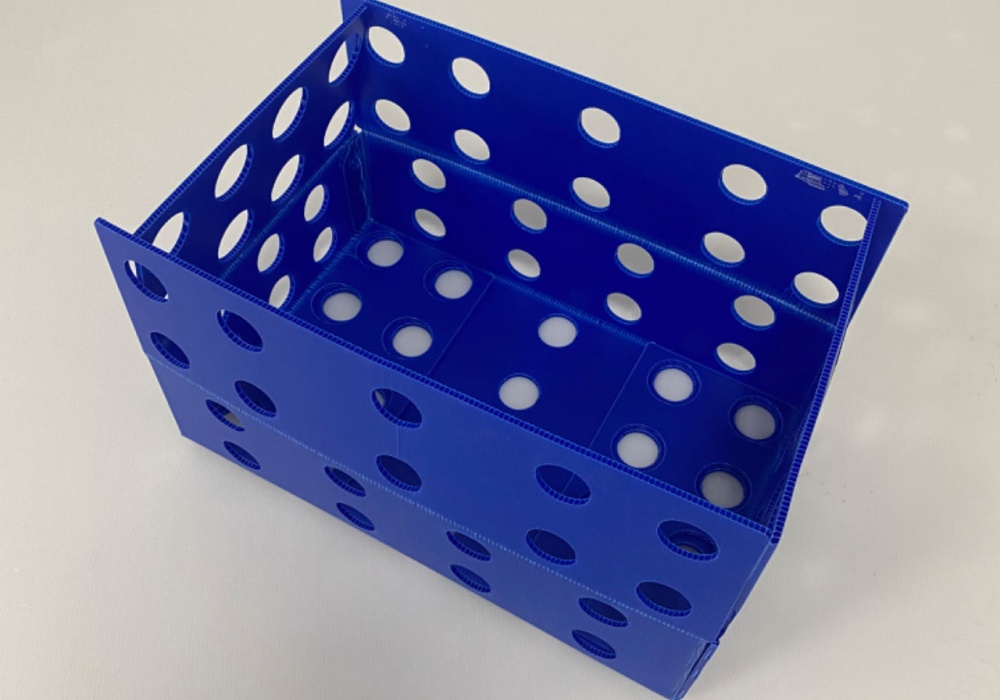

Product Details

| Parameter | Description |

|---|---|

| Material | Polypropylene (PP) or High-Density Polyethylene (HDPE) |

| Dimensions | Customizable, typically based on specific needs and applications |

| Capacity | Varies depending on size and design, from small household bins to large industrial containers |

| Durability | High, resistant to impact, moisture, and chemicals |

| Weight | Lightweight yet sturdy, facilitating ease of handling and maneuverability |

| Recyclability | Fully recyclable, contributing to environmental sustainability |

| Color Options | Wide range available, including standard colors like green, blue, black, gray, as well as custom color options for specific branding or organizational needs |

| Design Features | May include handles, locking lids, interlocking mechanisms, and venting systems for odor control |

| Application Scenarios | Suitable for various environments such as homes, offices, schools, hospitals, outdoor events, and more |

| Customization | Can be customized in terms of size, color, printing patterns, and additional features to meet specific requirements |

| Maintenance | Easy to clean with soap and water, and can be wiped down or hosed off as needed |

| Cost-Effectiveness | Offers a good balance between performance, durability, and affordability compared to other materials |

Product Gallery

Corrugated plastic trash bin What is the manufacturing process

1. Raw Material Preparation

- Material Selection: Generally, polypropylene (PP) or high-density polyethylene (HDPE) is chosen as the base material due to its excellent durability, recyclability, and processability. In some cases, engineering plastics like polycarbonate (PC) or ABS may be used to meet specific requirements.

- Inspection and Pretreatment: After procurement, the raw materials undergo rigorous quality inspections to ensure their purity, particle size, and other indicators meet processing standards. Then, they are precisely weighed according to the predetermined formula and prepared for subsequent production processes.

2. Sheet Formation

- Extrusion Molding: The plastic raw materials are fed into an extruder, where they are melted into a uniform melt under high temperature and pressure. This melt is then shaped into plastic sheets of specific dimensions through a customized die. Parameters such as the extruder’s temperature, pressure, and die design can be adjusted to control the sheet’s thickness, texture, and other properties.

- Cooling and Setting: The extruded plastic sheets need to be cooled rapidly to solidify and retain their desired shape and size. Cooling can be achieved through air cooling or water cooling methods. The cooling rate must be carefully controlled; too rapid cooling may cause warping or cracking, while too slow cooling would reduce production efficiency.

3. Cutting and Printing

- Sheet Cutting: Based on the design specifications of the trash bin, the cooled and solidified plastic sheets are precisely cut into various parts such as the body, lid, and handles using cutting equipment like guillotines or laser cutters.

- Printing Patterns and Logo: If patterns, texts, or logos need to be added to the surface of the trash bin, printing processes can be employed. Common printing methods include silk screen printing, heat transfer printing, and UV printing. These techniques ensure that the patterns are clear and firmly attached to the plastic sheets, enhancing the aesthetics and identifiability of the trash bin.

4. Assembly and Welding

- Parts Assembly: The individual components of the trash bin are assembled according to the design requirements. Screws, nuts, and adhesives are commonly used to join these parts together, forming the basic framework of the trash bin.

- Welding Reinforcement: To enhance the structural strength and sealing performance of the trash bin, critical areas such as seams, bottom connections, etc., undergo welding processes. Methods like hot plate welding, hot gas welding, and ultrasonic welding are used to securely bond the plastic parts, ensuring the overall quality and stability of the trash bin.

5. Accessory Installation

- Various accessories are installed based on the trash bin’s intended function and usage requirements. These include latches, hinges, casters, handles, etc. Specialized tools and equipment are used to ensure the accurate placement and firm attachment of these accessories, facilitating easy handling and use of the trash bin.

6. Quality Inspection

- Appearance Check: A comprehensive visual inspection of the assembled trash bin is conducted to check for any surface defects such as scratches, bubbles, deformations, or color variations, ensuring that the product meets cosmetic quality standards.

- Dimensional Measurement: The dimensions of the trash bin are accurately measured using measuring tools to confirm that its length, width, height, diameter, and other specifications conform to the design requirements.

- Performance Testing: Various performance tests are carried out on the trash bin, including load-bearing capacity tests, pressure resistance tests, and sealing tests. These tests verify that the trash bin has sufficient strength and functionality for practical applications. Only products that pass all quality inspections are allowed to proceed to the next stage or be sold to customers.

Corrugated plastic trash bin

certified by

Upgrade Your Waste Management with Our Durable Corrugated Plastic Trash Bins – Built to Last, Designed for Style!

Specifications

Place of Origin: China (Mainland)

Material: PP

Color: Black/White/Gey/Blue/Custom

Size: Can be customized

OEM/ ODM: Accept

MOQ: 500pcs

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon