Corrugated plastic shipping boxes are primarily made from high-density polyethylene (HDPE) or polypropylene (PP) plastic particles, along with additives for enhanced performance. The manufacturing process begins by extruding these plastics into continuous sheets through heated extruders, followed by cooling and cutting to desired dimensions. The sheets are then printed with identification and other information. Corrugations are pressed into the sheets to improve foldability and structural strength, and the boxes are assembled by folding and securing the components through welding, riveting, gluing, or snapping. Finally, the boxes undergo quality inspections for appearance, dimensions, load-bearing capacity, and stacking safety, and are then packaged for protection during transportation and storage.

In summary, the production of corrugated plastic shipping boxes involves selecting appropriate materials, extruding and cooling the sheets, printing, pressing corrugations, assembling the boxes with secure connections, conducting thorough quality checks, and packaging for safe transport.

corrugated plastic shipping boxes What is the market outlook

The market outlook for corrugated plastic shipping boxes is quite positive, driven by several key factors:

Market Drivers

- E-commerce Growth

- The continuous expansion of the e-commerce industry is a significant driver. With more consumers shopping online, there is an increasing demand for durable and reliable packaging solutions that can protect products during transit. Corrugated plastic shipping boxes are well-suited for this purpose as they offer good strength and can be reused multiple times, making them cost-effective in the long run.

- Sustainability Trends

- As sustainability becomes a higher priority for businesses and consumers alike, corrugated plastic boxes are gaining attention. They are recyclable and can be reused, which aligns with the goals of reducing waste and environmental impact. Many companies are seeking eco-friendly packaging alternatives, and corrugated plastic boxes fit this bill.

- Lightweight and Durability

- These boxes are lightweight yet durable. They provide sufficient protection for a wide range of products while being easier to handle and transport compared to some other types of packaging materials. Their durability also means that they can be used in various modes of transportation without fear of damage.

- Customization and Branding Opportunities

- Corrugated plastic boxes can be easily customized with different colors, logos, and designs. This allows businesses to enhance their brand visibility and create a unique unboxing experience for customers. Customization is a growing trend in the packaging industry, and these boxes can meet that demand.

Challenges

- Cost Competition

- While corrugated plastic boxes have advantages, they may face cost competition from traditional cardboard boxes, especially in the short-term. Cardboard boxes are often cheaper upfront, although they may not have the same reusability and durability as corrugated plastic. However, as the focus on sustainability and long-term costs increases, the price difference may narrow.

- Awareness and Adoption

- There is still a need to raise awareness among some businesses about the benefits of corrugated plastic shipping boxes. Some companies may be hesitant to switch from the established packaging materials they have been using. Convincing them of the advantages in terms of durability, sustainability, and long-term cost savings will be crucial for market growth.

Future Prospects

- Technological Advancements

- Ongoing research and development could lead to further improvements in the manufacturing process and properties of corrugated plastic boxes. For example, innovations in material science may result in even more sustainable and stronger variations of these boxes.

- Expanding Applications

- Currently, corrugated plastic shipping boxes are used in various industries such as food and beverage, pharmaceuticals, and industrial goods. In the future, their applications could expand further as new markets discover their benefits. They may also find more use in cold chain logistics due to their insulating properties when modified.

In conclusion, the market outlook for corrugated plastic shipping boxes is promising. Driven by e-commerce growth, sustainability trends, and their own unique properties, they are expected to continue gaining market share despite some challenges. Technological advancements and expanding applications will likely contribute to their growth in the coming years.

Product Details

| Parameter Item | Description |

|---|---|

| Material | Typically made of high-density polyethylene (HDPE) or polypropylene (PP). These materials offer good impact resistance, chemical resistance, and weather resistance, ensuring the durability and longevity of the boxes during shipping and storage. |

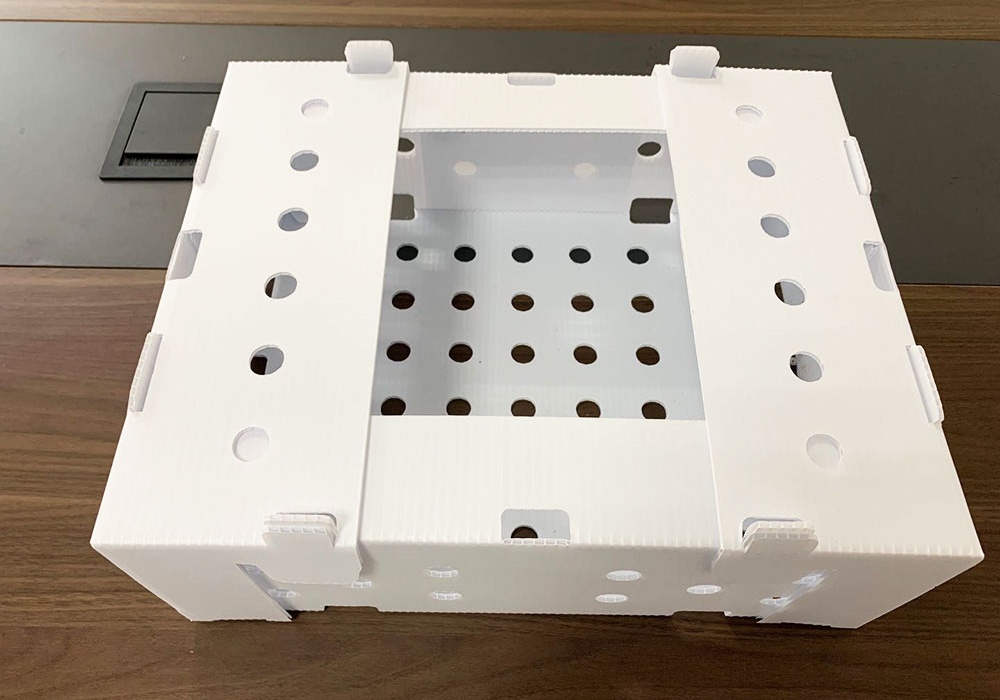

| Dimensions | Corrugated plastic shipping boxes come in various sizes to accommodate different products. The dimensions can range from small boxes for light items to large containers for bulk goods or oversized products. Commonly available sizes may include lengths ranging from a few inches to several feet, widths from a few inches to a couple of feet, and heights varying accordingly. |

| Load Capacity | The load capacity depends on the size and construction of the box. Smaller boxes can hold lighter items, while larger boxes are designed to carry heavier loads. For example, some standard-sized boxes can hold up to 500 pounds or more, making them suitable for heavy products like machinery parts or large quantities of smaller goods. |

| Compression Strength | Corrugated plastic boxes have good compression strength, which allows them to withstand stacking and pressure during transit. The specific compression strength varies based on the material thickness and design of the box, but they are generally capable of handling multiple layers of boxes without collapsing. |

| Water Resistance | Most corrugated plastic shipping boxes have excellent water resistance. They can repel water and protect the contents from moisture damage, which is particularly important for products that are sensitive to water, such as electronics, pharmaceuticals, or certain food items. |

| Temperature Tolerance | These boxes can withstand a wide range of temperatures, both hot and cold. This makes them suitable for shipping items in various environments, including refrigerated or frozen goods, as well as products that may be exposed to high temperatures during transportation. |

| Durability | Corrugated plastic boxes are highly durable and can be reused multiple times. They are resistant to wear and tear, punctures, and impacts, which reduces the need for frequent replacements and contributes to cost savings over time. |

| Weight | The weight of the boxes themselves is relatively light compared to their load capacity. This makes them easier to handle during loading, unloading, and transportation, and also helps reduce shipping costs by minimizing the overall weight of the cargo. |

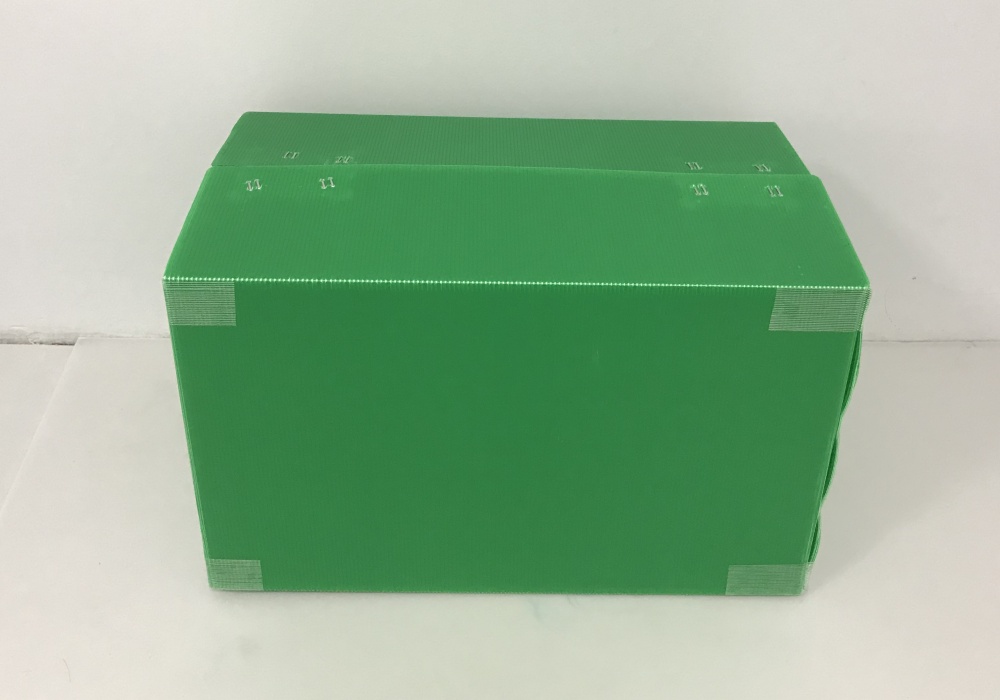

| Customization | Many manufacturers offer customization options for corrugated plastic shipping boxes. This includes different colors, printing of logos or product information, and special features such as handles, locking mechanisms, or dividers to meet specific packaging and branding requirements. |

Product Gallery

corrugated plastic shipping boxes have advantages

Corrugated plastic shipping boxes have several advantages. Here are the key points:

Durability and Strength

- High Impact Resistance: Corrugated plastic is designed to withstand heavy impacts, making it ideal for protecting fragile or delicate items during shipping and handling. This durability helps to prevent damage to the contents, reducing the risk of returns or replacements.

- Structural Integrity: The corrugated design adds rigidity and structural strength to the box, allowing it to maintain its shape and form even when stacked or under pressure. This ensures that the box can hold its contents securely and safely throughout the supply chain.

Lightweight and Cost-Effective

- Ease of Handling: Despite their strength, corrugated plastic boxes are relatively lightweight compared to other types of packaging materials. This makes them easier to handle, transport, and maneuver, which can improve efficiency in warehouse and logistics operations and reduce labor costs.

- Reduced Shipping Costs: The lightweight nature of these boxes also contributes to lower shipping costs. Carriers often charge based on weight, so using lighter packaging materials can result in significant cost savings, especially for long-distance shipments or large volumes of goods.

Versatility and Adaptability

- Customizable Sizes and Shapes: Corrugated plastic boxes can be easily customized to meet specific size and shape requirements. They can be molded or assembled into various configurations, allowing them to accommodate a wide range of products, from small electronic components to large machinery parts.

- Reusable and Recyclable: These boxes are highly durable and can be reused multiple times, which not only reduces the need for frequent replacements but also contributes to environmental sustainability. When they eventually reach the end of their life cycle, they can be recycled, further reducing waste and promoting a circular economy.

Weather Resistance and Protection

- Moisture Resistance: Corrugated plastic is naturally resistant to moisture and water, making it an excellent choice for shipping goods in wet or humid environments. It can protect products from rain, snow, or condensation during transit, ensuring that they arrive dry and in good condition.

- Temperature Tolerance: The material has a high tolerance to extreme temperatures, both hot and cold. This makes it suitable for use in various climates and for shipping temperature-sensitive products without the need for additional insulation or protective measures.

Hygiene and Cleanliness

- Easy to Clean and Sanitize: Corrugated plastic boxes are smooth and non-porous, which makes them easy to clean and sanitize. This is particularly important in industries such as food and pharmaceuticals, where hygiene and cleanliness are critical. It also helps to prevent the buildup of bacteria or contaminants, ensuring the safety and quality of the products being shipped.

Branding and Marketing Opportunities

- Customizable Appearance: The surface of corrugated plastic boxes can be easily customized with different colors, logos, and designs. This allows businesses to enhance their brand visibility and create a unique unboxing experience for customers. Customized packaging can also help to differentiate products on the shelf and attract consumer attention.

In summary, corrugated plastic shipping boxes offer a range of advantages that make them a popular choice for many industries. Their durability, lightweight nature, versatility, weather resistance, hygiene properties, and branding opportunities combine to provide an effective and efficient packaging solution for a wide variety of products.

corrugated plastic shipping boxes

certified by

Eco-Friendly Packaging Solutions: Experience the Future with Our Corrugated Plastic Shipping Boxes – Durable, Reusable, and Sustainably Smart!

Specifications

Place of Origin: China (Mainland)

Material: PP

Color: Black/White/Gey/Blue/Custom

Size: Can be customized

OEM/ ODM: Accept

MOQ: 500pcs

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon