The market outlook for Corrugated Plastic Drilling Core Boxes is promising, with a steady demand expected from industries such as geology, mining, and construction. These boxes are valued for their durability, lightweight nature, and ability to protect core samples during transportation and storage. As exploration activities continue to increase globally, the need for reliable and efficient drilling core storage solutions is likely to drive market growth in the coming years. Additionally, advancements in plastic materials and manufacturing technologies may lead to innovative product enhancements, further expanding the market potential. Overall, the Corrugated Plastic Drilling Core Box market is poised for steady expansion, supported by ongoing industry demand and continuous technological improvements.

Corrugated plastic drilling core box advantages

The advantages of Corrugated Plastic Drilling Core Boxes are as follows:

Durability and Strength

- High load-bearing capacity: These boxes can withstand significant weights, allowing them to hold heavy drilling cores without deformation or damage. This is crucial for safely transporting core samples from the drilling site to the laboratory or storage area.

- Resistance to impact: The corrugated design provides excellent impact resistance, protecting the cores inside from accidental drops, bumps, or knocks during handling and transportation.

- Long service life: They are highly durable and have a long service life, which makes them a cost-effective solution in the long run. They can withstand the rigors of repeated use in demanding drilling environments.

Protection of Core Samples

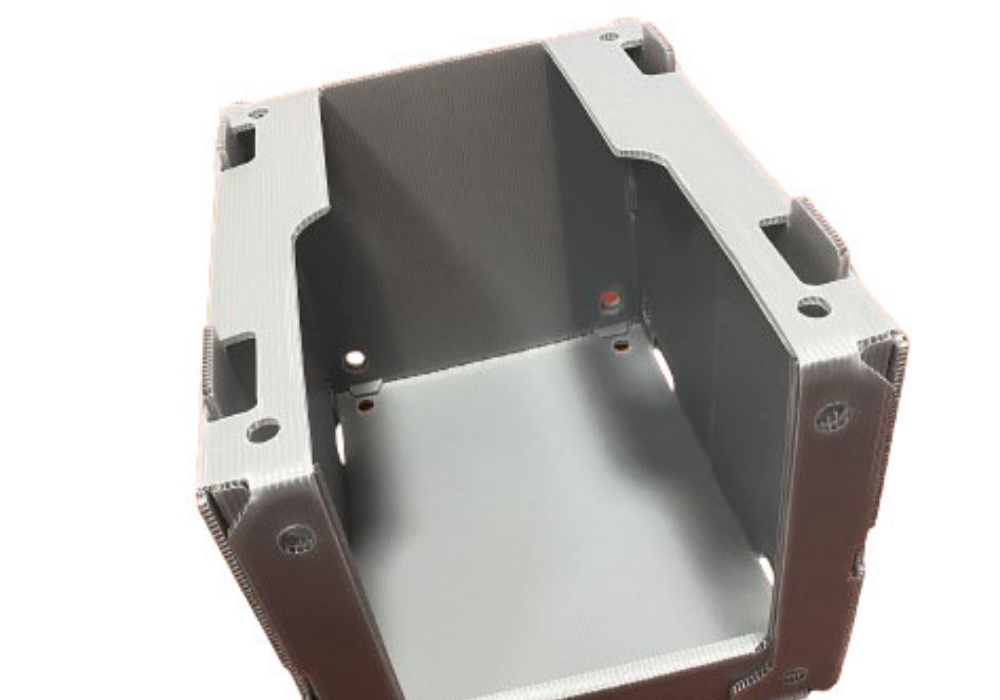

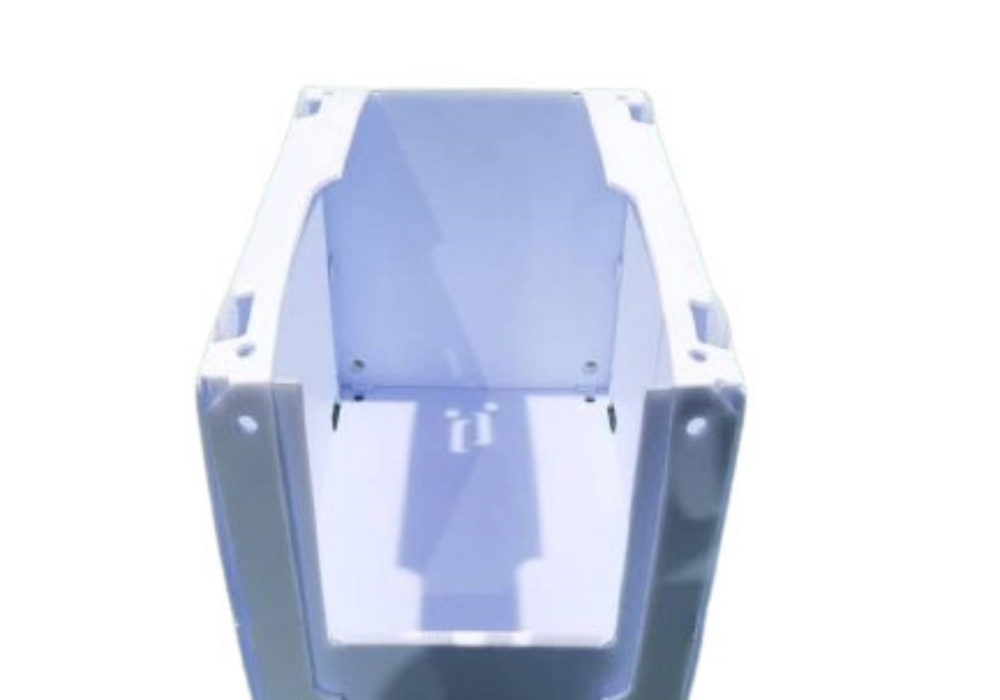

- Sealed environment: Many corrugated plastic drilling core boxes come with tight-sealing lids that create a dust-proof and moisture-proof environment. This helps to prevent contamination of the core samples and ensures their integrity for accurate analysis.

- Cushioned interior: Some models may have cushioned interiors or foam inserts that provide additional protection by absorbing shocks and vibrations, further reducing the risk of core sample damage.

Lightweight and Easy to Handle

- Convenient transportation: Despite their strength, corrugated plastic drilling core boxes are relatively lightweight compared to other materials like metal. This makes them easy to carry, load, and unload from vehicles, reducing the physical strain on workers and improving work efficiency.

- Stackable design: They often have a stackable design, which allows for efficient storage and space utilization. When not in use, they can be neatly stacked, saving valuable storage space at the drilling site or in the laboratory.

Versatility and Customization

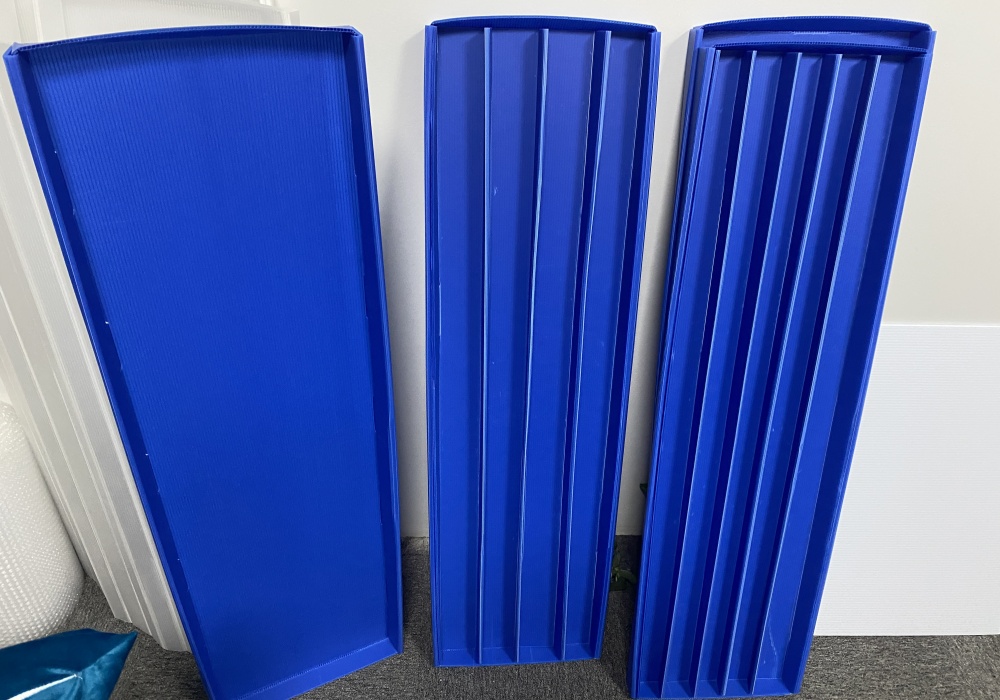

- Adjustable size: These boxes come in various sizes and can be customized to fit different lengths and diameters of drilling cores. This versatility ensures that they can accommodate a wide range of core samples from different drilling projects.

- Labeling and identification: They usually have smooth surfaces that are easy to label and mark. This facilitates the accurate identification and tracking of core samples, ensuring that they are properly organized and documented throughout the drilling process.

Cost-Effectiveness

- Affordable material: Compared to some other materials used for drilling core storage, such as metal or specialized plastics, corrugated plastic is relatively inexpensive. This makes it an attractive option for drilling companies looking to manage costs while still ensuring the quality and safety of their core samples.

- Low maintenance: Corrugated plastic drilling core boxes require minimal maintenance. They are easy to clean and do not need special treatments or coatings to maintain their performance, further contributing to their overall cost-effectiveness.

In summary, corrugated plastic drilling core boxes offer a range of advantages that make them a popular choice in the drilling industry. From durability and protection to ease of handling and cost-effectiveness, these boxes play a vital role in ensuring the safe and efficient management of drilling core samples.

Product Details

Here is a summary of the key parameters for Corrugated Plastic Drilling Core Boxes:

| Parameter | Description |

|---|---|

| Material | High-density polyethylene (HDPE) or polypropylene (PP) |

| Thickness | Ranges from 2mm to 12mm or more, depending on specific requirements |

| Size | Customizable dimensions based on core size and length needs; standard sizes available for common core diameters |

| Weight Capacity | Designed to hold heavy drilling cores securely without deformation |

| Durability | High resistance to impact, moisture, and chemicals, ensuring long service life |

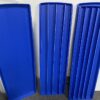

| Color Options | Available in various colors such as white, black, red, green, blue, etc. |

| Stacking Strength | Stackable design with interlocking features for efficient storage and space utilization |

| Sealing Mechanism | Tight-sealing lids or covers to protect cores from dust and moisture |

| Customization Options | Can include foam inserts, dividers, handles, labeling, and printing for branding and identification purposes |

| Certification | May have certifications such as ISO 9001:2008, depending on manufacturer and application requirements |

| Applications | Geological exploration, mining, construction, oil and gas industry, research laboratories, etc. |

Product Gallery

Corrugated plastic drilling core box What is the price range

The price range of Corrugated Plastic Drilling Core Boxes varies depending on several factors. Here are some specific details about the prices:

Based on Specifications and Size

- Small or Thin Models: Boxes with thinner thicknesses and smaller sizes generally have lower prices. For example, small boxes with thicknesses in the range of 2mm to 4mm may cost from a few dollars to around ten dollars each. Such boxes, which are suitable for light drilling or occasions with small sample quantities, might be priced between 5−5−10.

- Medium-Sized Standard Models: Common medium-thickness and standard-size boxes usually cost between 10and10and30. For instance, boxes with thicknesses of 5mm – 8mm and dimensions suitable for general core storage fall within this price range. These boxes can meet the needs of most general drilling projects.

- Large or Thick Models: Larger and thicker boxes, which can carry heavier and longer drill cores and use more materials, will have higher prices ranging from tens of dollars to over a hundred dollars. For example, special-specification boxes with thicknesses reaching 10mm or more and larger sizes could cost more than $100.

Based on Color and Customization Level

- Standard Colors: Common colors like white and black, especially for mass-produced standard models, have relatively stable and affordable prices within the aforementioned ranges for different specifications.

- Custom Colors or Printing: If customers require specific colors or need custom printing on the boxes, such as adding logos, patterns, or text, it will increase the cost. The price may be 20% – 50% or even more higher than that of ordinary colored and non-printed boxes, depending on the complexity of customization and printing technology.

Based on Quantity Purchased and Sales Channels

- Bulk Purchasing: When purchasing in large quantities, suppliers usually offer certain discounts. The more boxes purchased at once, the lower the unit price. For example, buying several thousand boxes at a time may reduce the price by 10% – 30% compared to individual purchases.

- Retail Purchasing: For small retail purchases, the price is generally calculated based on the retail price, which is relatively high. Moreover, the price may vary depending on different retailers and regions, but it is usually higher than the unit price of bulk purchases.

In summary, the price range of Corrugated Plastic Drilling Core Boxes is broad, ranging from a few dollars to over a hundred dollars. The specific price needs to be determined according to actual needs and market conditions. When purchasing, it is recommended to choose the appropriate specifications, colors, and customization levels based on actual needs and consider bulk purchasing to reduce costs.

Corrugated plastic drilling core box

certified by

Secure your cores with precision! Our Corrugated Plastic Drilling Core Boxes offer unmatched durability and protection for your valuable geological samples. Engineered to withstand rugged conditions, these boxes ensure your cores stay intact and organized. Trust in the strength of corrugated plastic for all your drilling needs.

Specifications

Place of Origin: China (Mainland)

Material: PP

Color: Black/White/Gey/Blue/Custom

Size: Can be customized

OEM/ ODM: Accept

MOQ: 500pcs

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon