The manufacturing process of Coroplast Warehouse Picking Bins includes the following steps: Firstly, select high-density polyethylene (HDPE) or polypropylene (PP) and other plastic materials, and make them into flat plates through extrusion. Then cut the plates into the desired size and shape for subsequent bending and assembling. After that, bend the plates into the basic frame structure of the picking bins by professional bending equipment and tools. Next, assemble the various components into a complete picking bin by welding, riveting or screw connection. Install accessories on the picking bins according to customer demands. Finally, conduct comprehensive quality inspections and proper packaging before shipment.

Coroplast Warehouse Picking Bins are the most popular in those industries

The reasons why Coroplast Warehouse Picking Bins are popular can be stated as follows:

Food Industry

- Health and Safety: They meet strict food safety standards, with materials that release no harmful substances, preventing food contamination and ensuring the safety of food during storage and transportation.

- Durability and Easy Cleaning: The material is solid and durable for long – term use, and the smooth surface is easy to clean and disinfect, maintaining the hygiene of the food storage environment.

- Space Optimization: They can be customized according to the different sizes and shapes of food, improving the utilization of warehouse space and facilitating the classified storage and management of food.

Pharmaceutical Industry

- Reliable Quality: With high strength and impact resistance, they can effectively ensure the safety of drugs during storage and transportation, reducing the risk of drug damage.

- Moisture and Dust Proof: Good sealing performance can effectively block air, moisture and dust, providing a stable storage environment for drugs and ensuring their quality.

- Convenient Management: They can be identified and tracked by means of labeling and barcoding, which is convenient for drug management and tracing and improves the accuracy and efficiency of work.

Electronics Industry

- Anti – Static Function: Some products are added with anti – static materials or coatings, which can prevent static electricity from damaging electronic products and protect the performance and quality of electronic components.

- Precise Fit Advantage: They can be customized according to the size and shape of electronic products to provide accurate storage space and avoid collision and damage of products during handling.

- Lightweight and Easy Handling: The material is light, which is convenient for operators to handle and organize, and helps to improve the efficiency of production and distribution.

Retail Industry

- Attractive and Practical Appearance: The beautiful design and various colors can enhance the display effect of goods, and at the same time, they have practicality and can meet the storage and display needs of goods.

- Flexible Combination Feature: They can be flexibly combined and adjusted according to different types of goods and promotional activities to adapt to market changes.

- Cost – Effective Advantage: The price is relatively low and the service life is long, which can reduce the operating costs of enterprises and improve economic benefits.

Logistics Industry

- Efficient Handling Characteristics: The reasonable structural design facilitates the loading, unloading and handling of goods, and can be used in combination with forklifts, shelves and other logistics equipment to improve the efficiency of logistics operations.

- Information Management Advantage: They can be combined with the information management system to achieve real – time tracking and management of goods, improving the accuracy and transparency of logistics operations.

- Environmentally Friendly and Energy – Saving Feature: The materials can be recycled, meeting environmental requirements and helping enterprises to achieve sustainable development goals.

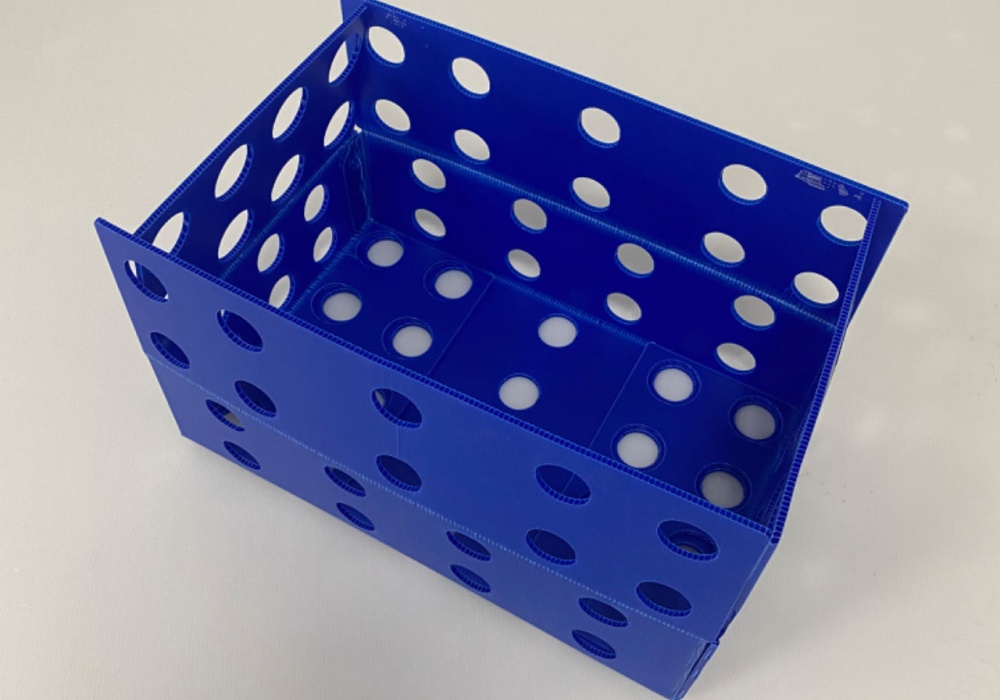

Product Details

Customized Correx Pick Bins are highly versatile and customizable storage solutions designed to meet the specific needs of various industries. Here is a table summarizing their key parameters:

| Parameter | Description |

|---|---|

| Material | High-density polypropylene (HDPE) or polypropylene (PP) |

| Thickness | 2mm to 15mm |

| Color Options | Customizable, typically including but not limited to blue, black, white, yellow, red, green, grey, etc. |

| Shape | Rectangular, square, round, or any custom shape as per requirement |

| Size | Custom dimensions based on specific needs, with no standard size limitation |

| Load Capacity | Dependent on the thickness and design, generally ranging from light to heavy loads |

| Surface Finish | Smooth or textured, can be printed or labeled easily |

| Resistance | Waterproof, moisture-resistant, and resistant to mold and mildew |

| Eco-Friendliness | Made from recyclable materials, reducing environmental impact |

| Stacking Feature | Designed to stack stably for efficient space utilization in warehouses |

| Printing Methods | Screen printing, UV coating, varnishing, glossy lamination, matte lamination, etc. |

| Usage | Widely used in logistics, e-commerce, food processing, cosmetics, pharmaceuticals, automotive, and other industries for picking and storing goods |

| Delivery Time | Typically 7-15 working days after receiving payment |

| MOQ (Minimum Order Quantity) | Varies by supplier, generally around 100 pieces or more |

| Certification | ISO9001, SGS, RoHS, and others, depending on the manufacturer’s compliance |

These parameters make Customized Correx Pick Bins suitable for a wide range of applications where durability, customization, and efficient space management are crucial.

Product Gallery

What is the price range for Coroplast Warehouse Picking Bins

Here are the price ranges for Coroplast Warehouse Picking Bins:

- Small Sizes: Generally, small Coroplast Warehouse Picking Bins have relatively lower prices, ranging from a few dollars to dozens of dollars. For example, some picking bins with small capacities and compact sizes may cost about 5−5−20.

- Medium Sizes: The price of medium – sized picking bins is usually between tens of dollars and more than a hundred dollars. For instance, the bins with moderate sizes that can meet the general warehouse item picking requirements may cost around 30−30−100.

- Large Sizes or Special Customization: Large Coroplast Warehouse Picking Bins or those customized according to specific customer needs may have higher prices, ranging from hundreds of dollars to several hundred dollars. Especially for large – scale customization orders that require special materials or structural design, the prices will increase accordingly.

Coroplast Warehouse Picking Bins

certified by

Elevate Your Warehouse Efficiency with Coroplast Picking Bins – The Ultimate Choice for Durability, Organization, and Seamless Operations.

Specifications

Place of Origin: China (Mainland)

Material: PP

Color: Black/White/Gey/Blue/Custom

Size: Can be customized

OEM/ ODM: Accept

MOQ: 500pcs

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon