When importing corrugated plastic separator sheets from China, it is crucial to consider several key points. First, quality control and certifications are paramount; ensure the products meet international standards and have necessary certifications. Second, communication with suppliers is vital; establish clear specifications, timelines, and payment terms to avoid misunderstandings. Third, logistics and shipping arrangements must be carefully planned to ensure safe and timely delivery. Additionally, understanding customs regulations and tariffs is essential to avoid any legal or financial issues. Lastly, conducting thorough market research and due diligence on potential suppliers can help mitigate risks and ensure a successful import process.

Corrugated plastic separator sheet What is the market outlook

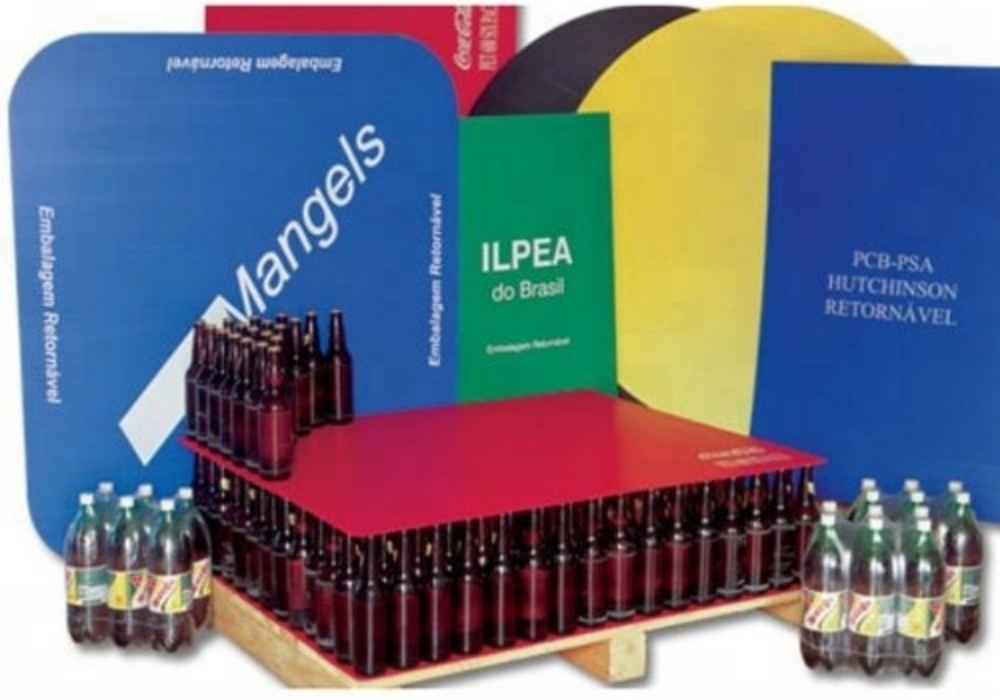

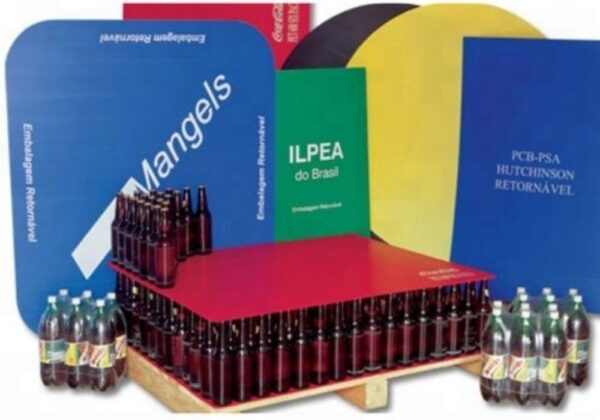

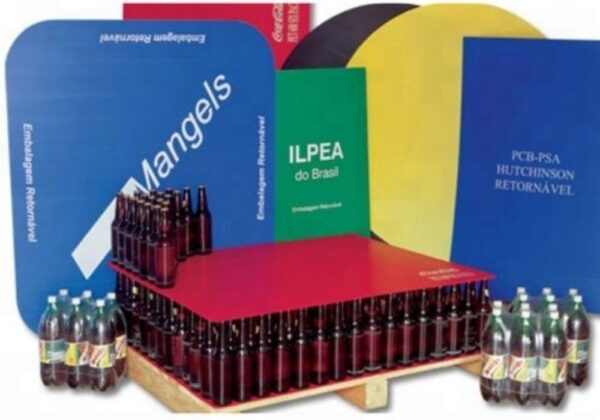

Wide range of applications

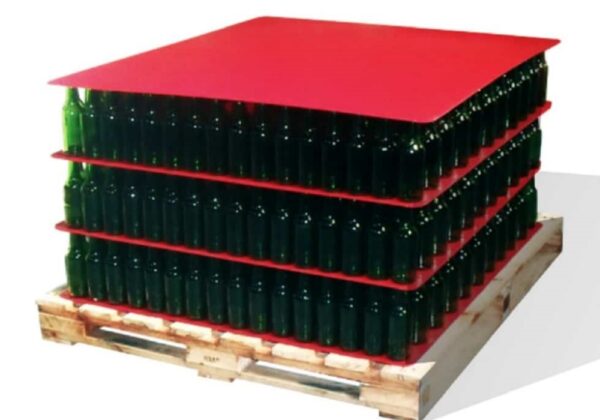

- Automobile parts industry: In the packaging and transportation of automotive parts, corrugated plastic separator sheets can provide good cushioning and separation, preventing mutual collision and friction between parts, and protecting the surface quality and accuracy of parts. With the continuous development of the automotive industry, the packaging requirements for parts are getting higher and higher, and the market demand for corrugated plastic separator sheets will also increase accordingly.

- Electronics and electrical appliances industry: Electronic products and electrical appliances need to use separators for separation and fixation during production, transportation, and storage, in order to prevent damage to the products. The anti-static property of corrugated plastic separator sheets can effectively protect electronic components and avoid the impact of static electricity on them, so they have broad application prospects in the electronics and electrical appliances industry.

- Pharmaceutical industry: The pharmaceutical industry has high requirements for product hygiene and safety. The non-toxic, odorless, and easy-to-clean characteristics of corrugated plastic separator sheets make them an ideal material for pharmaceutical packaging. In addition, corrugated plastic separator sheets can also be customized according to the different shapes and sizes of drugs, improving the efficiency and quality of packaging.

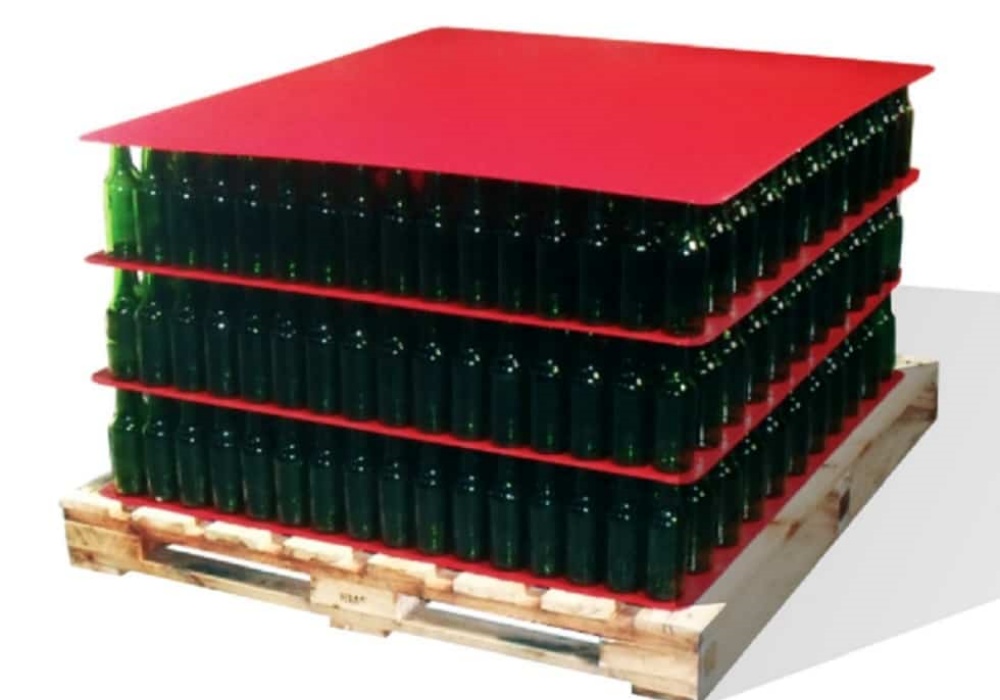

- Logistics and warehousing industry: In the logistics and warehousing process, corrugated plastic separator sheets can be used for the separation, classification, and protection of goods, improving logistics efficiency and the safety of goods. With the rapid development of e-commerce, the demand for corrugated plastic separator sheets in the logistics industry is also increasing.

Enhanced environmental awareness: As people’s environmental awareness continues to improve, the demand for recyclable and degradable materials is increasing. Corrugated plastic separator sheets are usually made of recyclable materials such as polypropylene (PP), which meet environmental requirements and can be recycled after use, reducing environmental pollution. Compared with traditional paper separators or wooden separators, corrugated plastic separator sheets are more environmentally friendly and can bring better environmental image to enterprises, thus being favored by more and more enterprises.

Outstanding performance advantages

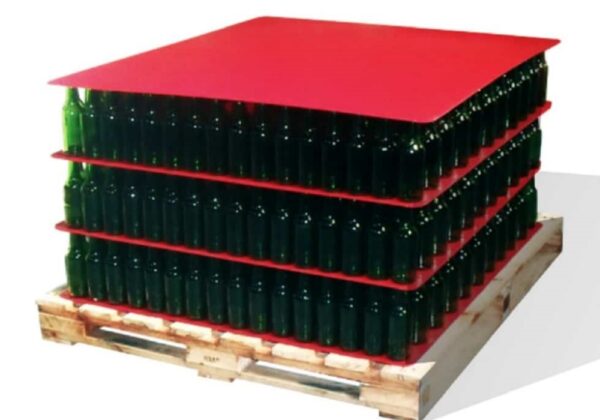

- Durability: It has high strength and toughness, can bear greater pressure and weight, and is not easily deformed or damaged. In the process of transportation and storage, it can effectively protect the safety of items.

- Moisture resistance: It has good moisture resistance and can remain dry in humid environments, preventing items from getting damp and moldy. This characteristic makes corrugated plastic separator sheets have great advantages in the application of food, pharmaceuticals, and other industries.

- Easy to clean: The surface is smooth, not easy to get dirty, and very convenient to clean. In the food, pharmaceutical, and other industries where hygiene is highly required, this characteristic is particularly important.

High degree of customization: It can be customized according to the needs of different customers, including dimensions, thickness, color, pattern, and other aspects. Enterprises can choose suitable corrugated plastic separator sheets according to their own product characteristics and packaging requirements, improve the effect of packaging and brand image.

Obvious market growth trend: According to relevant market research reports, the global corrugated plastic separator sheet market shows an annual growth trend. For example, it is predicted that the scale of the market will reach a certain amount in 2029, with a high compound annual growth rate.

In conclusion, the corrugated plastic separator sheet, with its wide range of applications, eco-friendly features, superior performance, and high degree of customization, is poised to have a bright future in the market. As the demand for high-quality, eco-friendly packaging materials continues to grow across various industries, corrugated plastic separator sheets are likely to become the preferred packaging solution for numerous enterprises, driving a continuous expansion of the market size.

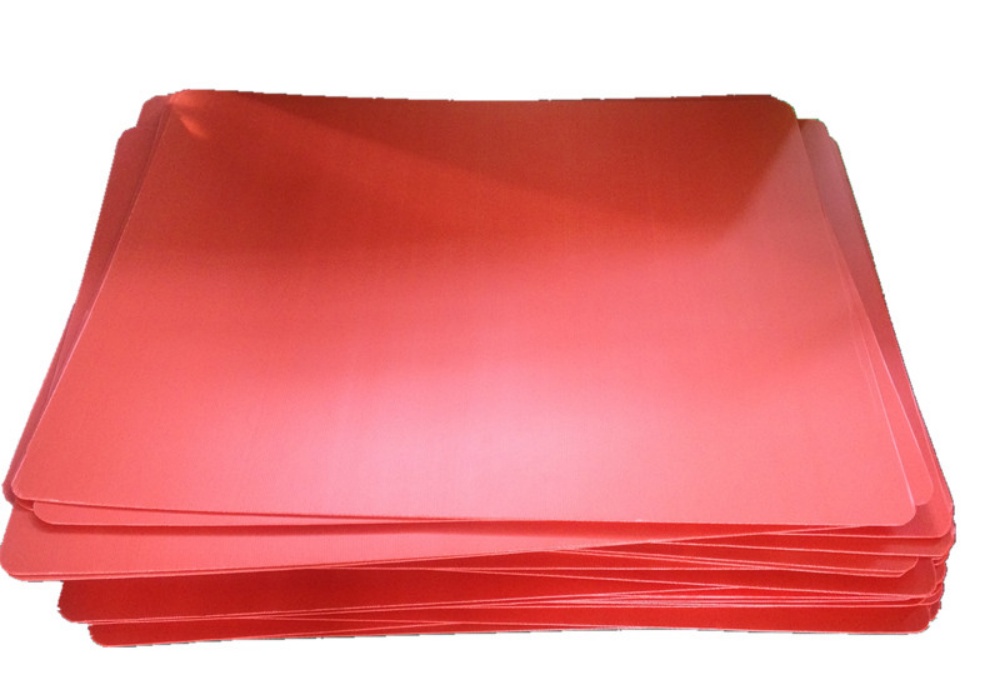

Product Details

| Parameter | Description |

|---|---|

| Material | Polypropylene (PP) is commonly used, known for its durability and recyclability. |

| Thickness | Typically ranges from 1mm to 5mm, depending on the application and load requirements. Thicker sheets offer better strength and durability. |

| Size | Standard sizes are available, but customization is possible based on specific needs. Common dimensions include 1000mm x 2000mm, 1200mm x 2400mm, etc. |

| Color | Available in various colors such as white, black, blue, green, yellow, etc. Custom colors can also be provided upon request. |

| Surface Treatment | Can be smooth or embossed. Embossed surfaces provide better slip resistance and aesthetic appeal. |

| Weight | Lightweight yet sturdy, making them easy to handle and install. The weight depends on the thickness and size of the sheet. |

| Temperature Resistance | Withstands a wide range of temperatures, typically from -20°C to 80°C. Some specialized sheets may have higher temperature resistance. |

| Chemical Resistance | Resistant to most chemicals, oils, and solvents, making them suitable for use in various industries. |

| Fire Resistance | Some corrugated plastic separator sheets are fire-resistant or self-extinguishing, providing an added safety feature. |

| Environmental Impact | Being recyclable and reusable, they have a lower environmental impact compared to other materials like wood or metal. |

| Applications | Widely used in automotive, electronics, pharmaceuticals, logistics, food packaging, and many other industries for separation, protection, and organization of goods. |

These parameters can vary based on the manufacturer and the specific requirements of the application. It is always recommended to consult with the supplier or manufacturer to get detailed information tailored to your needs.

Product Gallery

Corrugated plastic separator sheet What is the price range

By Material and Thickness

- Ordinary Polypropylene (PP) Material: Corrugated plastic separator sheets with a thickness of around 2-5 millimeters cost roughly between 0.40and0.40and0.80 per square meter; if the thickness reaches 6-12 millimeters, the price per square meter may be around 1.00to1.00to2.50.

- Anti-static or Special Material: Corrugated plastic separator sheets with anti-static functions are relatively more expensive, with a price per square meter of about 1.50to1.50to3.00. The specific price depends on the anti-static performance indicators and the quality of the material.

By Size

- Small Size: For some small corrugated plastic separator sheets used in electronic equipment packaging, small parts separation, etc., with sizes ranging from 10 cm×10 cm to 30 cm×30 cm, the price for each piece may be around 0.10to0.10to0.50.

- Large Size: Larger corrugated plastic separator sheets used for packaging large equipment and separating goods in logistics transportation, with dimensions of 1 m×2 m and above, may have a price per square meter of about 1.00to1.00to3.00.

By Color

- Conventional Colors: The prices of corrugated plastic separator sheets in conventional colors such as white, black, and blue are relatively stable, generally around 0.50to0.50to1.50 per square meter.

- Customized Colors: If special colors are required, such as fluorescent colors, metallic colors, etc., the price may be 20%-50% higher than that of ordinary colors.

By Purchase Quantity

- Small Quantity Purchase: If the purchase quantity is small, such as within a few hundred pieces, it may not be possible to enjoy the discount price of bulk purchase, and the price for each piece may be around 1.00to1.00to3.00.

- Large Quantity Purchase: Bulk purchase can get certain discounts. When the purchase quantity reaches several thousand pieces or even tens of thousands of pieces, the price for each piece may be reduced to about 0.50to0.50to1.00.

In conclusion, the price of corrugated plastic separator sheets is influenced by many factors and has a large fluctuation range. When purchasing, it is recommended to choose the appropriate product according to the specific needs and budget, and consult multiple suppliers to get a more favorable price and service.

Corrugated plastic separator sheet

certified by

Unveil the Future of Organization: Experience the Durability and Versatility of Corrugated Plastic Separator Sheets – Where Strength Meets Sustainability. Elevate Your Space with Style and Efficiency Today!

Specifications

Thickness: a few millimeters to several tens of millimeters

Size: Customized

Color: Customized

Hardness: determined by its material and design

Density: about 0.91g/cm³

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon