The price range for corrugated plastic wardrobe boxes varies based on size, durability, customization, and order quantity, with budget options costing 10to10to30 per box, standard sizes from 30to30to60, premium or customized boxes ranging from 60to60to150 or more, and potential discounts available for bulk purchases, while high-end or specialty options could exceed 150to150to500 per box.

Corrugated plastic wardrobe boxes are most popular in those industries

Corrugated plastic wardrobe boxes are most popular in several industries due to their durability, versatility, and cost-effectiveness. Here are some of the key industries that commonly use these types of boxes:

1. Retail and E-Commerce

- Apparel and Fashion: These boxes are ideal for shipping clothes, shoes, and accessories due to their lightweight yet sturdy nature.

- Online Retailers: E-commerce businesses use them for secure shipping of products, ensuring items arrive safely at customers’ doorsteps.

2. Manufacturing and Industrial

- Automotive Parts: Used for the safe transport of car parts and components.

- Electronics: Protect sensitive electronic equipment during shipping and storage.

3. Moving and Storage

- Household Goods: Perfect for packing and moving clothes, linens, and other household items.

- Self-Storage Units: Renters use these boxes for organizing and protecting their belongings.

4. Food and Beverage

- Catering Services: Utilized for transporting food items, utensils, and linens.

- Delivery Services: Ensure the safe delivery of meal kits and gourmet foods.

5. Healthcare and Pharmaceuticals

- Medical Supplies: Used for the safe transportation of medical instruments, pharmaceuticals, and personal protective equipment (PPEs).

- Laundry Services: Hospitals and clinics use these boxes for clean linens and uniforms.

6. Events and Entertainment

- Event Planning: Ideal for transporting event decor, costumes, and equipment.

- Photography and Videography: Protective case for equipment during travel to different locations.

7. Hobbies and Crafts

- Craft Fairs and Markets: Artisans and crafters use these boxes to transport their goods securely.

- Scrapbooking and Quilting: Safe storage and transportation of materials.

These industries benefit from the robustness, reusability, and customizable features of corrugated plastic wardrobe boxes, making them a versatile solution for a wide range of packaging and transportation needs.

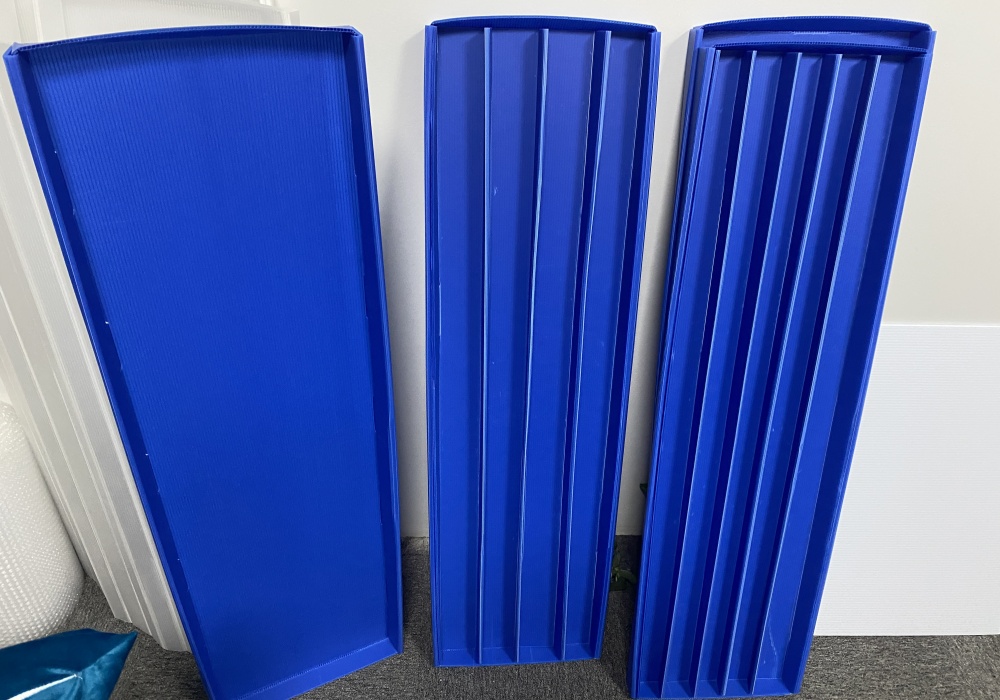

Product Details

Summary of Parameters for Corrugated Plastic Wardrobe Boxes

| Parameter | Description |

|---|---|

| Material | High-density polypropylene (HDPE) or polyethylene (PE) for durability and recyclability. |

| Size Options | Standard sizes include small, medium, large, and extra-large, with custom sizes available. |

| Color Options | Typically available in a range of colors such as white, blue, red, yellow, and transparent. |

| Thickness | Generally ranges from 2mm to 5mm, providing various levels of durability and protection. |

| Weight Capacity | Can hold from 20kg to 150kg depending on size and thickness. |

| Open/Close Mechanism | Options include zippers, snap closures, and lockable lids for security. |

| Ventilation | Some boxes come with ventilation holes or gaps to prevent moisture buildup and odors. |

| Water Resistance | Usually water-resistant, suitable for outdoor use and humid environments. |

| Stackable Design | Most models are stackable for efficient storage and transport. |

| Reusability | Designed for multiple uses, promoting sustainability and cost-effectiveness. |

| Customization Options | Customizable with logos, labels, and specific color schemes for branding or organizational needs. |

| Temperature Tolerance | Withstands a wide range of temperatures, suitable for both cold and hot environments. |

| Collapsible Option | Some designs are collapsible for easy storage when not in use. |

| Assembly Type | No tools required for assembly; typically easy to set up and break down. |

| Sustainability | Made from recyclable materials, contributing to reduced environmental impact. |

| Common Uses | Ideal for clothing storage, shipping, moving, food transportation, and industrial applications. |

This table outlines the key parameters that define corrugated plastic wardrobe boxes, highlighting their versatility, durability, and suitability for various industries and applications.

Product Gallery

Corrugated plastic wardrobe box What is the manufacturing process

The manufacturing process of corrugated plastic wardrobe boxes typically includes the following steps:

Material Preparation

- Raw Material Selection: Choose high-quality polypropylene (PP) or high-density polyethylene (HDPE) as the main raw material, and select suitable colorants, ultraviolet absorbers, anti-oxidants, etc., according to the product design requirements.

- Mixing and Stirring: Add the selected auxiliary materials into the raw material in proportion, and stir evenly through a mixer to ensure the uniform dispersion of various additives in the material.

Sheet Production

- Extrusion: The evenly mixed raw material is sent to an extruder, where it is melted under high temperature and pressure, and then extruded from a specific die head to form a flat sheet.

- Cooling and Solidification: The extruded sheet is rapidly cooled through a cooling system to solidify and form a solid sheet with a certain thickness and strength.

Corrugation Processing

- Pre-treatment of Corrugated Cardboard: If the design requires corrugated cardboard, the flat sheet needs to be preliminarily processed into corrugated cardboard first. This usually involves gluing two or more layers of flat sheets together and then passing them through a corrugating machine to form a wave-shaped corrugated cardboard.

- Combining with Flat Sheet: The prepared corrugated cardboard is combined with other flat sheets again through gluing or other methods to form a multi-layer composite structure, which will serve as the side and bottom walls of the wardrobe box.

Cutting and Shaping

- Cutting: Use a cutting machine such as a die-cutting machine or a laser cutting machine to cut the combined sheet according to the predetermined size and shape of the wardrobe box, forming various parts such as front, back, sides, top, bottom, and doors.

- Edge Treatment: Process the edges of the cut parts, such as trimming, chamfering, and rounding corners, to make them smoother and safer to use.

Assembly

- Frame Assembly: Assemble the cut and edge-treated parts into a frame by connecting them with connectors, snaps, or adhesive. The commonly used connection methods include slotted connections, tongue and groove connections, and rivet connections.

- Door Installation: Install the door on the front of the frame according to the design requirements. The installation method can be hinge connection or sliding rail installation.

Surface Treatment

- Cleaning: Clean the surface of the assembled wardrobe box to remove dust, oil stains, and other impurities, so that the subsequent surface treatment effect is better.

- Printing: If the customer has printing requirements, carry out printing treatment at this stage. Common printing methods include screen printing, offset printing, and digital printing. Through printing, you can add patterns, logos, instructions and other information to the wardrobe box.

- Coating: Apply a layer of protective coating on the printed surface of the wardrobe box, such as a light oil or matte oil, to enhance its wear resistance, scratch resistance, and weather resistance.

Quality Inspection and Packaging

- Quality Inspection: Inspect the appearance, dimensions, structural strength, and surface quality of the wardrobe box. Check whether there are defects such as cracks, bubbles, deformation, discoloration, etc. Ensure that the product meets relevant standards and customer requirements.

- Packaging: After passing the quality inspection, wrap the wardrobe box with protective film or place it in a suitable packaging box for protection, and then label it for identification. Finally, store it in the warehouse for sale or shipment.

Corrugated plastic wardrobe box

certified by

Organize in Style, Simplify with Elegance – Discover the Future of Closet Care!

Specifications

Thickness: a few millimeters to several tens of millimeters

Size: Customized

Color: Customized

Hardness: determined by its material and design

Density: about 0.91g/cm³

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon