The price range for corrugated box plastic used for okra varies depending on factors such as quality, specifications, and suppliers. Generally, it can range from several cents to a few dollars per piece. To get the most accurate and up-to-date pricing, it’s recommended to consult with specific manufacturers or suppliers directly.

corrugated box plastic for Okra is most popular in those industries

Corrugated box plastic for Okra is most popular in the following industries:

- Fresh Produce Packaging Industry: It is widely used for packaging fresh okra and other vegetables, providing good protection and ventilation.

- Agricultural Sector: Farmers and agricultural cooperatives prefer it for transporting okra from fields to markets or processing centers.

- Retail Industry: Supermarkets and grocery stores often use corrugated box plastic for displaying and selling fresh okra.

- Food Processing Industry: It can be used in the processing and distribution of frozen or dried okra products.

- Eco-friendly Packaging Industry: Given its recyclable and reusable properties, it is favored by those who prioritize sustainable packaging options.

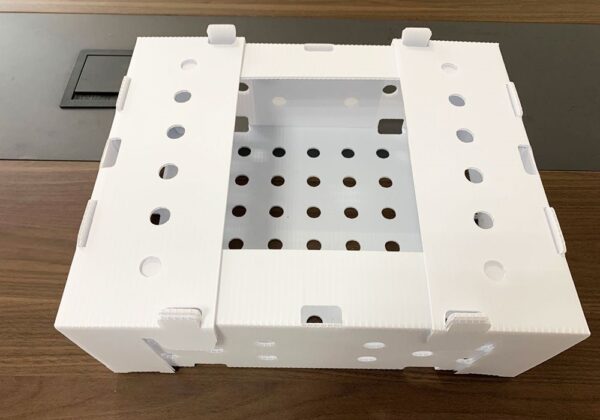

Product Details

| Parameter Item | Data |

|---|---|

| Material | PP (Polypropylene) or other food-grade plastics |

| Density | Around 0.9g/cm³ |

| Thickness | Varies based on specific product, commonly between 2mm to 5mm |

| Size (LWH) | Customizable based on okra length and packaging needs, typical length around 25cm-30cm |

| Weight Capacity | Depends on size and design, can hold several kilograms of okra |

| Compression Strength | High enough to protect okra from damage during handling and transportation |

| Temperature Resistance | Generally resistant to temperatures within the cold chain range for fresh produce |

| Color | Commonly green or transparent to show the okra’s color, can also be customized |

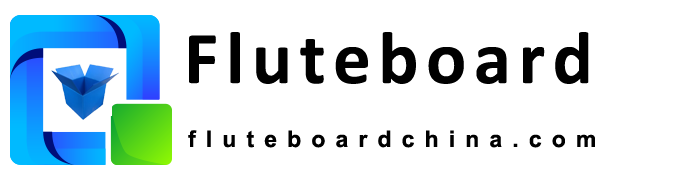

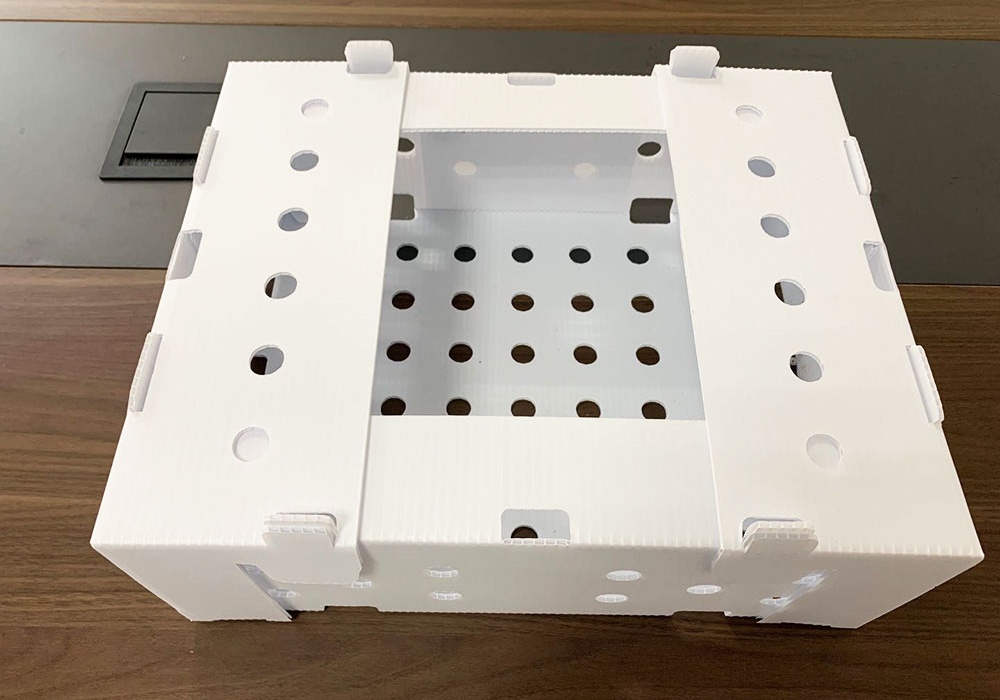

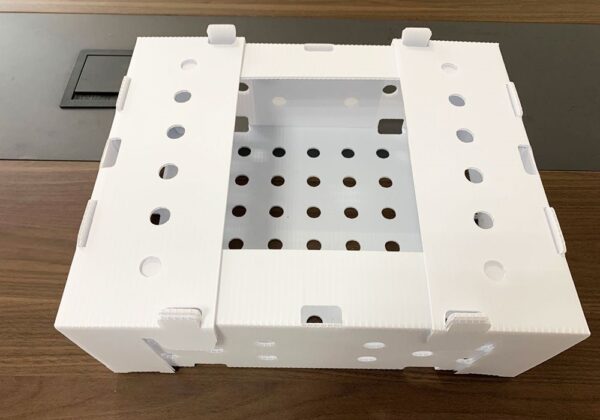

Product Gallery

corrugated box plastic for Okra What is the manufacturing process

The manufacturing process of corrugated box plastic for Okra generally includes the following steps:

- Material Selection and Preparation: Choose high-quality polypropylene (PP) or other food-grade plastic materials. The materials are carefully inspected and prepared, such as cleaning and drying if necessary.

- Sheet Extrusion: The selected plastic material is fed into an extruder. In the extruder, the material is melted and then formed into a continuous sheet through a specific die head under high temperature and pressure.

- Corrugation Forming: The flat sheet is then passed through a corrugating machine. This machine has rollers with specific patterns that press the sheet to create the characteristic corrugated shape. The depth and density of the corrugations can be adjusted according to different requirements.

- Cutting and Shaping: After corrugation, the large sheet is cut into the desired sizes for the boxes using cutting equipment. At this stage, accurate measurements and cuts are crucial to ensure the boxes fit together perfectly.

- Printing (if needed): If there are labeling or branding requirements, printing can be done at this stage. Using specialized plastic printing methods, patterns, logos, instructions, etc. can be printed on the surface of the corrugated plastic.

- Assembling and Finishing: The cut parts are assembled into boxes. This may involve gluing, welding, or other methods to join the various components. Finally, any rough edges are smoothed, and the boxes may undergo a quality check to ensure they meet the required standards.

corrugated box plastic for Okra

certified by

Premium Okra, Perfectly Packaged in Eco-Friendly Corrugated Plastic Boxes – Nature’s Goodness, Sustainably Delivered!

Specifications

Thickness: a few millimeters to several tens of millimeters

Size: Customized

Color: Customized

Hardness: determined by its material and design

Density: about 0.91g/cm³

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon