The manufacturing process of Corflute picking bins for warehouse involves material selection, sheet production by extruding PP into corrugated sheets, cutting and shaping into parts, assembling and fixing with connectors or welding, surface treatment for appearance and functionality, followed by quality inspection, and ultimately packaging for storage or shipment.

Corflute picking bins for warehouse What is the market outlook

Corflute picking bins for warehouse market prospects are very promising. Here’s the analysis:

Market Demand

- E-commerce Industry: With the continuous growth of the e-commerce industry, the demand for efficient and orderly warehouse operations is also increasing. Corflute picking bins can help improve picking efficiency, reduce errors, and are suitable for the fast-paced work environment of e-commerce warehouses.

- Third-Party Logistics: Third-party logistics companies need to handle a large number of goods from different clients. Corflute picking bins can provide better protection for goods and improve the efficiency and accuracy of space utilization.

- Manufacturing Enterprises: Manufacturing enterprises also have storage and transportation needs for raw materials and finished products. Corflute picking bins can be used in the storage and distribution process of raw materials, helping enterprises improve logistics efficiency.

Advantages of Products

- Durability and Reusability: Made from high-density polypropylene (PP) material, corflute picking bins have excellent durability and impact resistance, and can be reused many times, reducing the cost of replacing packaging materials.

- Lightweight and Space-Saving: Compared with traditional wooden or metal picking bins, corflute picking bins are lighter in weight, making them easier to handle and operate during picking and transportation. At the same time, they can be nested when not in use, saving storage space.

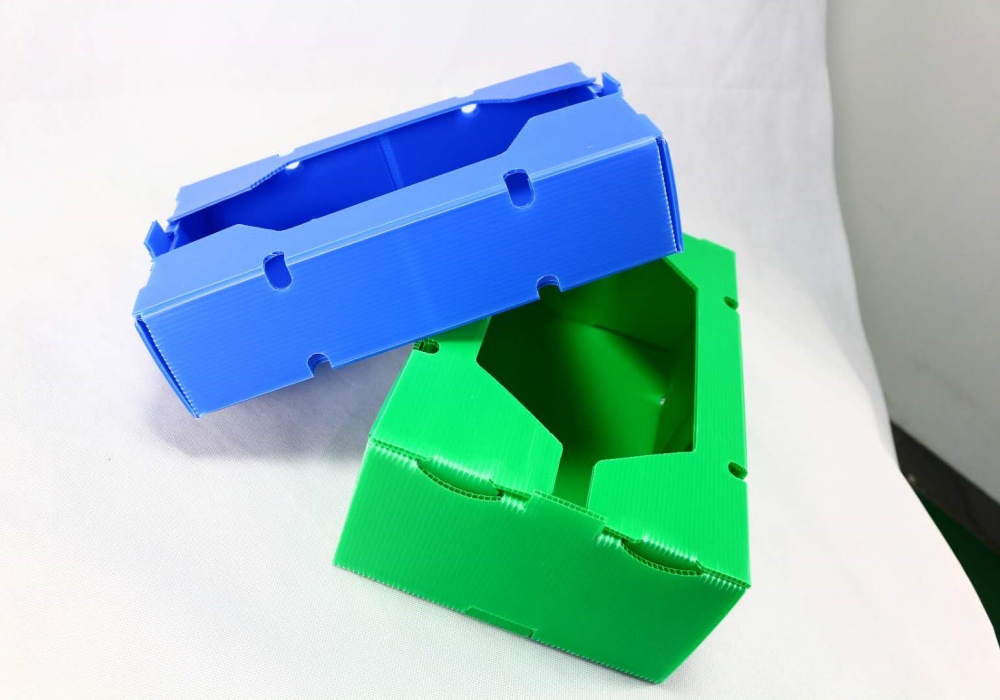

- Customizable: Manufacturers can customize the size, shape, color, and other aspects of corflute picking bins according to the needs of customers, meeting the personalized requirements of different industries and enterprises.

Industry Development Trends

- Green Environmental Protection: With the increasing emphasis on environmental protection, more and more enterprises are paying attention to the environmental performance of packaging materials. Corflute picking bins made from recyclable PP material are in line with the trend of green development and have broad application prospects.

- Automated and Intelligent: With the continuous development of technology, the degree of automation and intelligence in warehouse management is getting higher and higher. Corflute picking bins can be combined with automated equipment and intelligent systems to further improve warehouse operation efficiency.

- Integration of Supply Chain: The supply chain integration is an important direction for the future development of the logistics industry. As an important part of the supply chain, corflute picking bins can play a role in improving the overall efficiency of the supply chain by optimizing the logistics process.

Challenges and Opportunities

- Challenges: Firstly, there is fierce market competition among corflute picking bins, with numerous manufacturers offering similar products, making it difficult for enterprises to stand out. Secondly, the price of corflute picking bins is relatively high compared to some traditional picking bins, which may affect their market acceptance. Lastly, with the continuous changes in market demands, enterprises need to continuously update their products to meet new demands.

- Opportunities: The application range of corflute picking bins continues to expand, presenting more market opportunities for enterprises. For example, in the cold chain logistics field, corflute picking bins with good insulation performance can meet the special requirements of cold chain transportation. In addition, as consumer awareness of brand and quality increases, enterprises that can provide high-quality and customized corflute picking bins will gain more market share.

In summary, the corflute picking bins for warehouse have broad market prospects, but enterprises also need to face certain challenges. By continuously improving product quality, reducing costs, expanding application ranges, and enhancing brand influence, enterprises can better seize market opportunities in the fierce market competition.

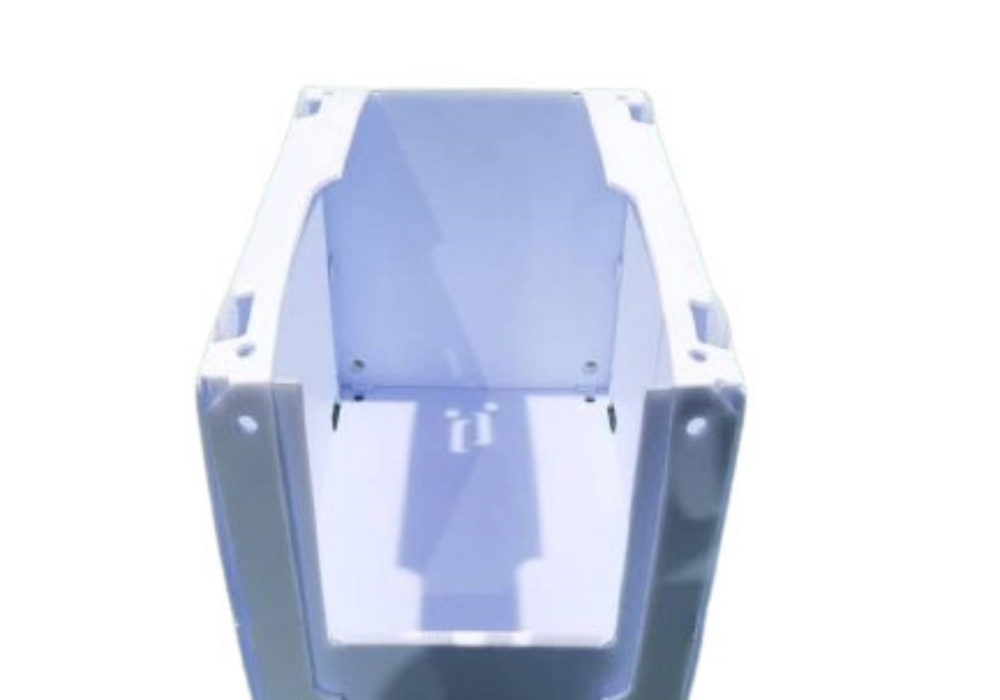

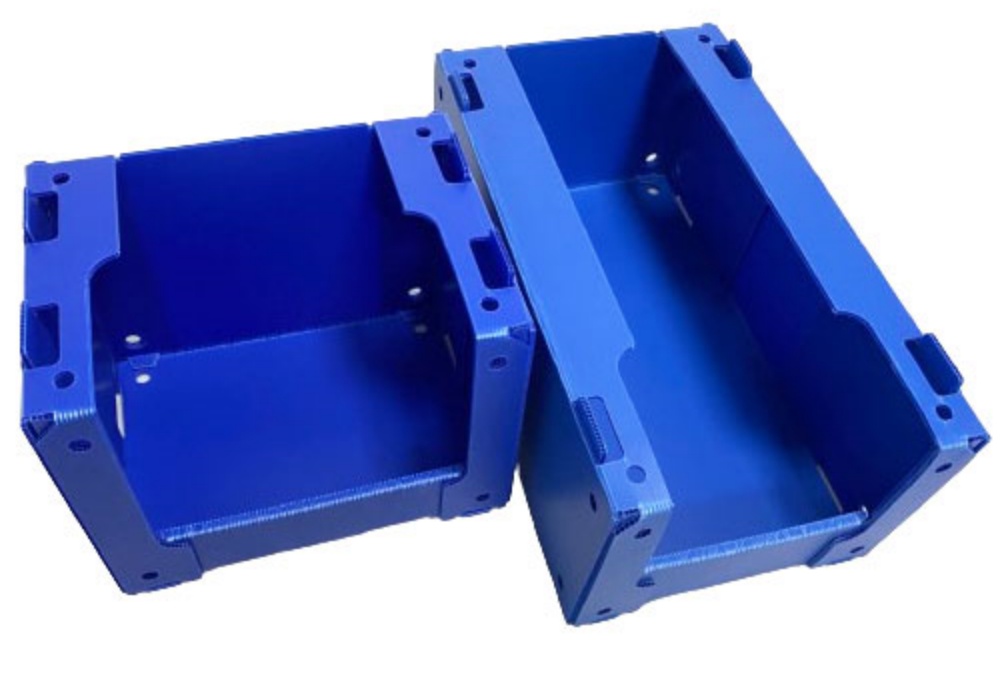

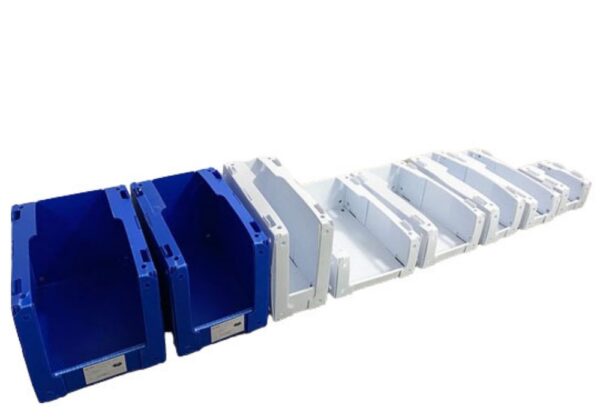

Product Details

Customized Correx Pick Bins are highly versatile and customizable storage solutions designed to meet the specific needs of various industries. Here is a table summarizing their key parameters:

| Parameter | Description |

|---|---|

| Material | High-density polypropylene (HDPE) or polypropylene (PP) |

| Thickness | 2mm to 15mm |

| Color Options | Customizable, typically including but not limited to blue, black, white, yellow, red, green, grey, etc. |

| Shape | Rectangular, square, round, or any custom shape as per requirement |

| Size | Custom dimensions based on specific needs, with no standard size limitation |

| Load Capacity | Dependent on the thickness and design, generally ranging from light to heavy loads |

| Surface Finish | Smooth or textured, can be printed or labeled easily |

| Resistance | Waterproof, moisture-resistant, and resistant to mold and mildew |

| Eco-Friendliness | Made from recyclable materials, reducing environmental impact |

| Stacking Feature | Designed to stack stably for efficient space utilization in warehouses |

| Printing Methods | Screen printing, UV coating, varnishing, glossy lamination, matte lamination, etc. |

| Usage | Widely used in logistics, e-commerce, food processing, cosmetics, pharmaceuticals, automotive, and other industries for picking and storing goods |

| Delivery Time | Typically 7-15 working days after receiving payment |

| MOQ (Minimum Order Quantity) | Varies by supplier, generally around 100 pieces or more |

| Certification | ISO9001, SGS, RoHS, and others, depending on the manufacturer’s compliance |

These parameters make Customized Correx Pick Bins suitable for a wide range of applications where durability, customization, and efficient space management are crucial.

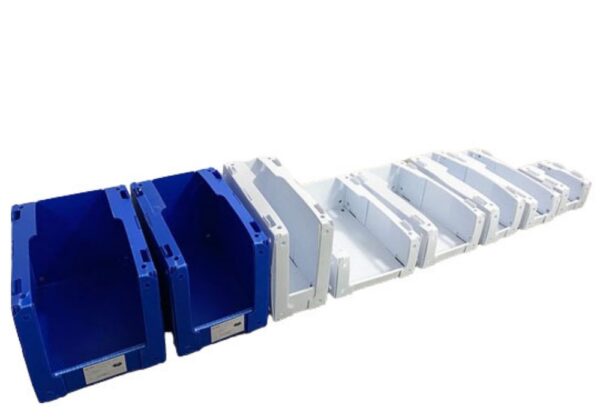

Product Gallery

Corflute picking bins for warehouse Advantages

The advantages of Corflute picking bins for warehouse are as follows:

Structural and Material Advantages

- Durable and Sturdy: Made from high-density polypropylene (HDPE) or polyethylene (PE), they have high strength and toughness, can bear the stacking of heavy goods without being damaged.

- Lightweight and Flexible: Compared with wooden or metal racks, Corflute picking bins are lighter, easier to carry and operate, which can improve the efficiency of warehouse operations.

- Moisture and Pest Resistant: They have good moisture-proof performance and can adapt to various humidity environments. Besides, they are not prone to pest infestation, effectively protecting goods.

High Space Utilization Efficiency

- Stackable and Nestable: When not in use, they can be stacked and nested with each other to save storage space and reduce warehousing costs.

- Diverse Sizes Available: A variety of sizes can be chosen according to the layout of the warehouse and the characteristics of the goods, improving the utilization of space.

Convenient Operation and Management

- Easy Identification and Classification: Different colors or identifications can be used for classification management, making the warehouse goods management clearer and more orderly, and facilitating the quick search and access to goods.

- Good Combined with Equipment: They can be well combined with automated equipment and intelligent systems to further improve the operation efficiency of the warehouse and achieve intelligent management.

- Convenient Cleaning and Maintenance: The surface is smooth and not easy to accumulate dust, so it is relatively simple to clean, and it is easy to maintain hygiene.

Good Environmental Protection and Economy

- Recyclable: In line with environmental protection requirements, they can be reused many times to reduce resource wastage and lower the operating costs of enterprises.

- Cost-Effective: Although the initial investment may be relatively high, they are durable and reusable in the long run, resulting in a relatively low total cost.

Safe and Highly Adaptable

- No Sharp Corners: The edges are round and smooth without sharp corners, reducing the risk of injury to personnel and goods.

- Widely Applicable: They can be used in various industries and scenarios such as food, medicine, electronics, etc. for warehousing, as well as in special environments like cold storage.

Corflute picking bins for warehouse

certified by

Maximize your storage potential with our corflute picking bins – the ultimate solution for warehouse efficiency and organization!

Specifications

Thickness: 2-12mm

Size: Customized

Color: Customized

Hardness: determined by its material and design

Density: 0.91-0.96 grams per cubic centimeter

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon