The manufacturing process of Customized Correx Pick Bin involves selecting high-quality PP material, customizing the size, shape, thickness, and color according to specific requirements, cutting and shaping the material using precision machinery, forming the corrugated structure through heat and pressure, assembling necessary components such as interlocking mechanisms or hinges, adding branding elements via various printing methods, conducting rigorous quality control inspections and testing for load-bearing capacity and durability, packaging the finished bins carefully to prevent damage during transit with materials like PE film and pallets, and shipping them to customers within 7 to 15 days depending on the order quantity and destination.

Customized Correx Pick Bin What is the market outlook

The future market prospects of Customized Correx Pick Bin are promising. Here’s a detailed analysis:

Market Demand and Growth Potential

- Increasing Adoption in Logistics: With the rapid development of e-commerce, the demand for efficient and convenient logistics solutions is on the rise. Customized Correx Pick Bin can be tailored to specific product sizes and shapes, improving space utilization and picking efficiency in warehouses, making it an ideal solution for the logistics industry.

- Wide Application Across Industries: Besides logistics, the food and beverage, cosmetics, pharmaceutical, and automotive industries also have high demands for customized packaging and storage solutions. Customized Correx Pick Bin can be designed according to the characteristics of different products, providing good protection and display effects.

Advantages and Differentiation

- Customization Flexibility: The size, shape, color, and other aspects of the pick bins can be customized based on customer requirements, meeting the personalized needs of different enterprises and enhancing the added value of the products.

- Durability and Reusability: Made from high-quality PP material, Correx Pick Bin has excellent durability and can withstand heavy use. It can be reused multiple times, reducing the need for businesses to frequently purchase new packaging containers, thereby lowering costs.

- Environmental Friendliness: As environmental awareness increases, more and more companies are paying attention to the environmental performance of packaging materials. Correx material is recyclable and meets environmental requirements, which is conducive to enhancing the environmental image of enterprises.

Technological Innovation and Development Trends

- Integration with Automated Equipment: In modern production and warehousing environments, automated equipment is widely used. Customized Correx Pick Bin can be designed to match automated storage and retrieval systems, improving overall operational efficiency.

- Data Tracking and Management Functions: By adding intelligent elements such as RFID tags, the pick bins can achieve data tracking and management functions, allowing real-time monitoring of the location and status of goods during storage and transportation, improving supply chain transparency.

Competitive Landscape and Cooperative Opportunities

- Competitive Advantage: Compared to traditional packaging containers, the customization advantages of Correx Pick Bin make it more competitive in the market. Enterprises that master the customized production process and technology can gain a larger market share.

- Industry Collaboration: The production of customized Correx Pick Bin involves multiple links such as raw material suppliers, processing manufacturers, and logistics companies. Strengthening cooperation within the industry chain can reduce costs, improve product quality, and promote the development of the entire industry.

In summary, the market prospects of Customized Correx Pick Bin are broad. With the continuous growth of market demand, the continuous advancement of technology, and the increasing emphasis on environmental protection, it is expected to have more applications in various industries in the future.

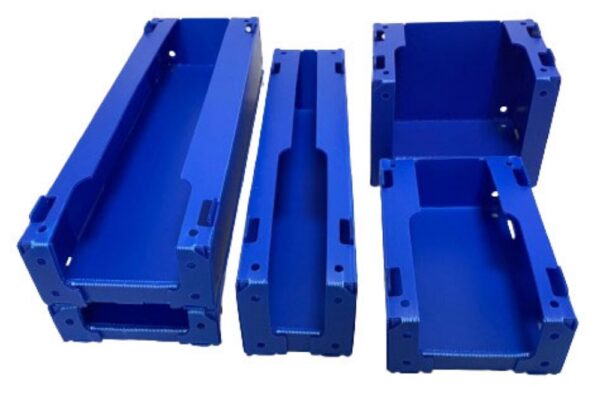

Product Details

Customized Correx Pick Bins are highly versatile and customizable storage solutions designed to meet the specific needs of various industries. Here is a table summarizing their key parameters:

| Parameter | Description |

|---|---|

| Material | High-density polypropylene (HDPE) or polypropylene (PP) |

| Thickness | 2mm to 15mm |

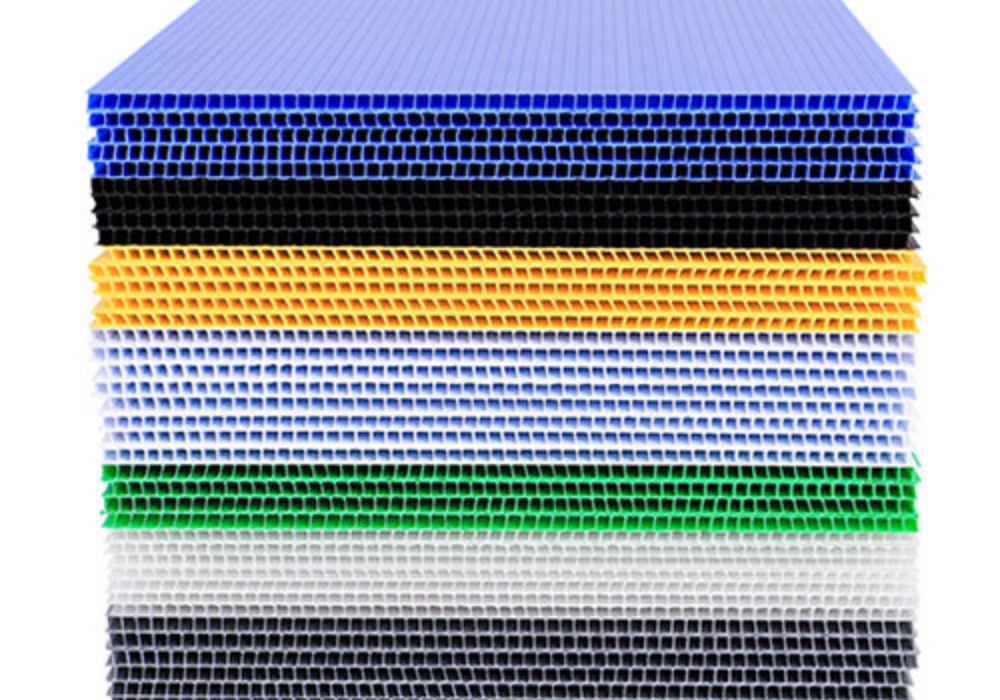

| Color Options | Customizable, typically including but not limited to blue, black, white, yellow, red, green, grey, etc. |

| Shape | Rectangular, square, round, or any custom shape as per requirement |

| Size | Custom dimensions based on specific needs, with no standard size limitation |

| Load Capacity | Dependent on the thickness and design, generally ranging from light to heavy loads |

| Surface Finish | Smooth or textured, can be printed or labeled easily |

| Resistance | Waterproof, moisture-resistant, and resistant to mold and mildew |

| Eco-Friendliness | Made from recyclable materials, reducing environmental impact |

| Stacking Feature | Designed to stack stably for efficient space utilization in warehouses |

| Printing Methods | Screen printing, UV coating, varnishing, glossy lamination, matte lamination, etc. |

| Usage | Widely used in logistics, e-commerce, food processing, cosmetics, pharmaceuticals, automotive, and other industries for picking and storing goods |

| Delivery Time | Typically 7-15 working days after receiving payment |

| MOQ (Minimum Order Quantity) | Varies by supplier, generally around 100 pieces or more |

| Certification | ISO9001, SGS, RoHS, and others, depending on the manufacturer’s compliance |

These parameters make Customized Correx Pick Bins suitable for a wide range of applications where durability, customization, and efficient space management are crucial.

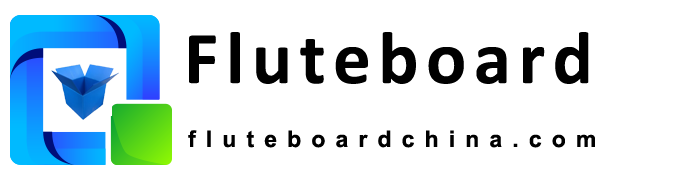

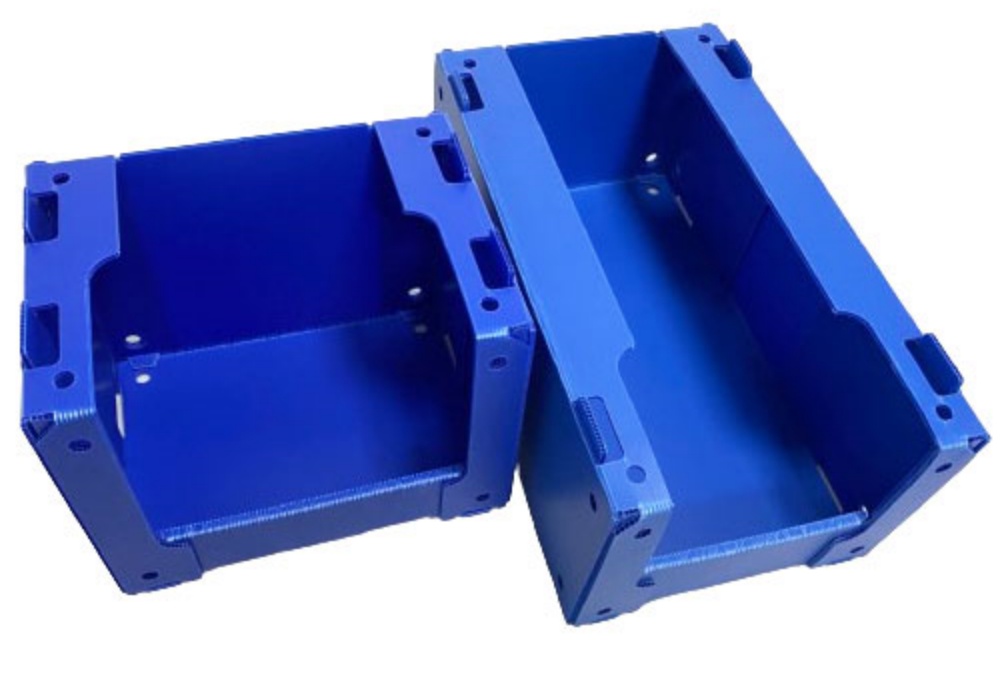

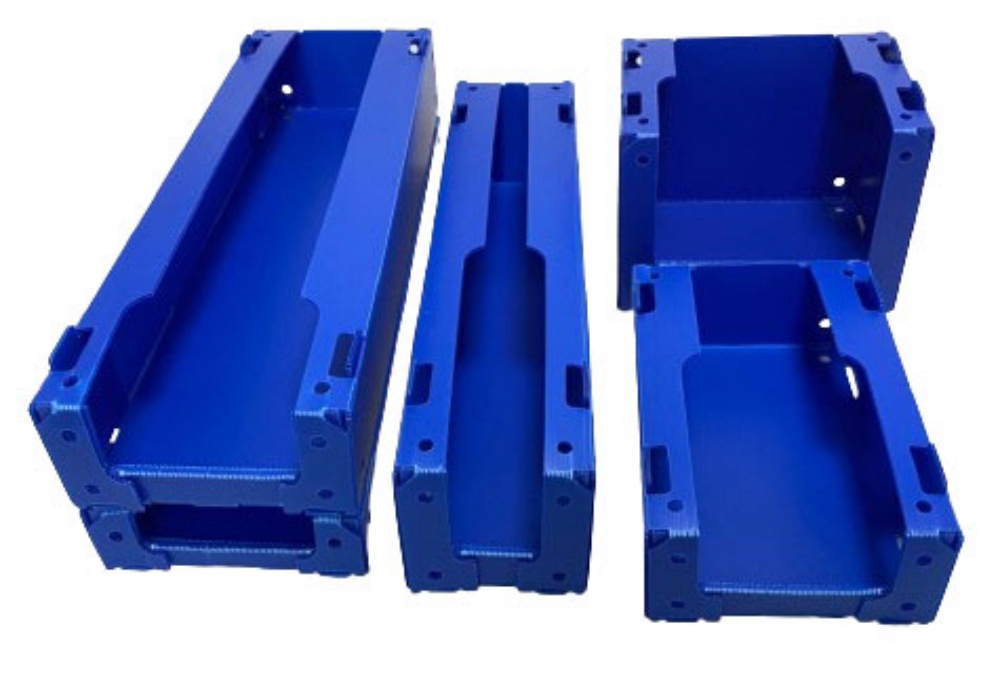

Product Gallery

Advantages of Customized Correx Pick Bin

The advantages of customized Correx Pick Bin are as follows:

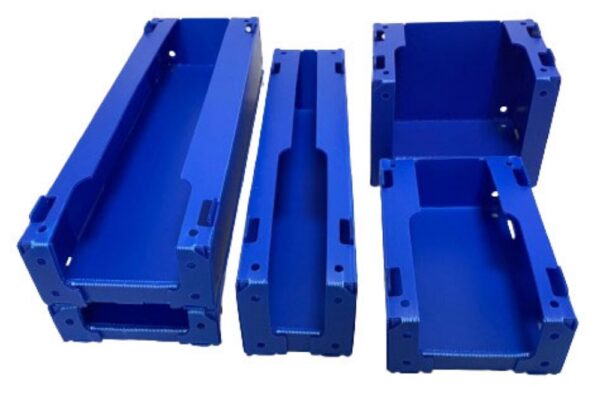

High Customization

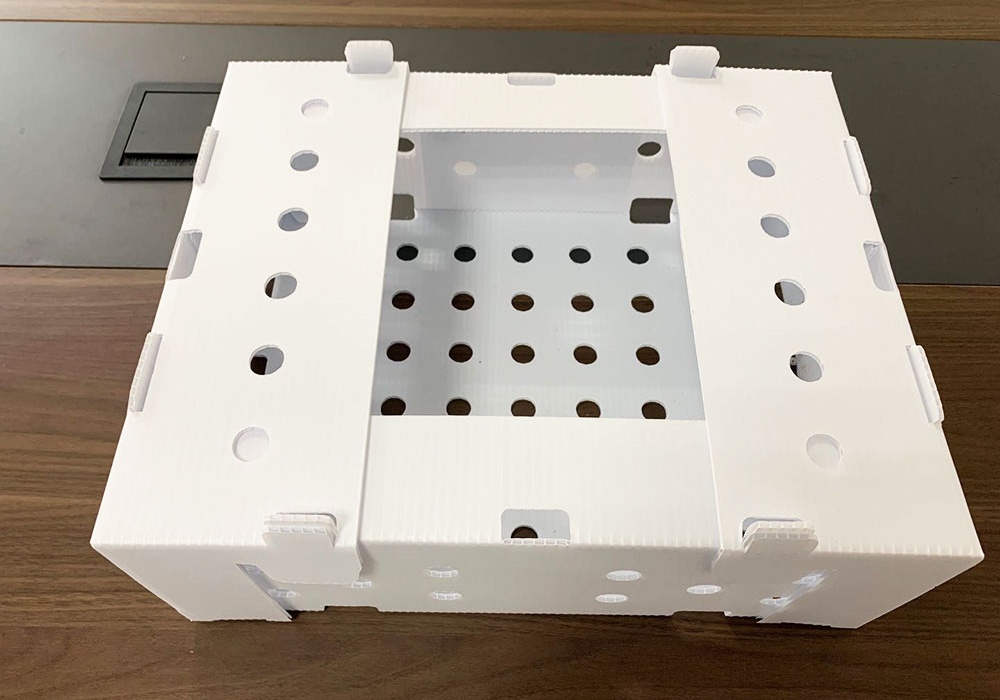

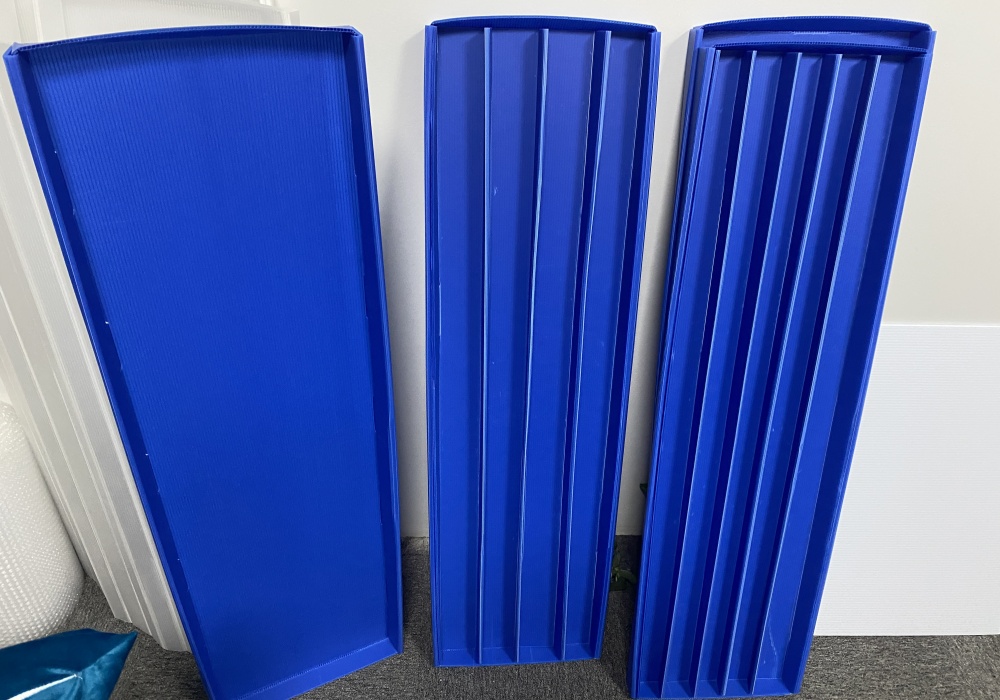

- Size Adaptability: It can be customized to match the shape, size, and storage needs of different goods exactly. Whether for large industrial components, small electronic elements, or items with irregular shapes, a perfectly matching Correx Pick Bin can be tailored for efficient storage, improving space utilization.

- Diverse Shapes: Besides common rectangles, it can also be made into special shapes such as circles and polygons to meet the storage requirements of specific items or special storage environments. For example, in a display warehouse, it can be customized into irregular-shaped Pick Bins that fit the display racks to enhance the display effect.

- Rich Color Options: Enterprises can choose specific colors according to their own brand image, warehouse area division, or management needs. For example, different colored Pick Bins can be used to distinguish between different types of products or goods in different states, making warehouse management more intuitive and convenient.

Strong Durability

- High-Quality Material: It is usually made of high-quality polypropylene (PP) material, which has excellent impact resistance, abrasion resistance, and weather resistance. It can withstand the pressure of heavy goods and is not easy to deform or break during long-term use, reducing the risk of goods damage due to packaging container damage.

- Stable Structure: Its unique corrugated board structure design makes the box have high strength and stability. Even when stacked multiply or subjected to certain external impacts, it can maintain the integrity of the box and effectively protect the internal goods from damage.

Lightweight and Easy to Operate

- Lightweight: Compared with some metal containers, Customized Correx Pick Bin is lighter, which is convenient for workers to carry, load and unload, and organize in the warehouse, reducing the labor intensity of workers and improving work efficiency.

- Easy to Stack: The design of the box enables it to be closely stacked together, and the stacked boxes have good stability. This not only saves storage space but also facilitates the classification, storage, and management of goods, making the warehouse layout more neat and orderly.

Cost-Effective

- Reusable: Customized Correx Pick Bin has a long service life and can be reused many times, reducing the packaging cost of enterprises. Compared with disposable packaging materials, it can save a lot of procurement costs in the long run.

- Low Maintenance Cost: Due to the characteristics of its material, this Pick Bin does not require special maintenance and care, and only needs to be cleaned regularly to keep it in good condition. Moreover, its surface is smooth and not easy to get dirty, so it is convenient to clean.

Environmentally Friendly and Sustainable

- Recyclable Material: Polypropylene is a recyclable environmentally friendly material that meets the requirements of environmental protection in modern society. When Customized Correx Pick Bin reaches the end of its service life, it can be recycled and reprocessed to make new products, reducing the impact on the environment.

- No Pollution: It does not release harmful substances during production and use, and is harmless to human health and environmental safety, helping enterprises achieve the goals of green production and sustainable development.

Good Compatibility and Expandability

- Compatible with Automated Equipment: It can be well coordinated with automated warehousing systems, logistics transportation equipment, etc. Its size and structure can be customized according to the requirements of automated equipment to ensure the smoothness and accuracy of goods in storage and transportation.

- Easy to Add Accessories: It is able to conveniently install various accessories, such as labels, barcodes, RFID tags, etc., to realize the information management and tracking of goods. It can also add partitions, pads, and other accessories as needed to further improve the protective performance and storage flexibility of goods.

Customized Correx Pick Bin

certified by

Elevate your organization game with our Customized Correx Pick Bins – where durability meets design, creating a storage solution that’s as smart as it is stylish!

Specifications

Thickness: 2-12mm

Size: Customized

Color: Customized

Hardness: determined by its material and design

Density: 0.91-0.96 grams per cubic centimeter

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon