When importing Coroplast sheets with printing from China, it’s crucial to ensure the products meet international quality standards, choosing reputable suppliers and comparing prices for the best value. Efficient logistics arrangement and smooth customs clearance are also vital, along with establishing good communication with suppliers for prompt issue resolution and reliable after-sales service.

What is the market outlook for Coroplast sheets with printing

Coroplast sheets with printing have broad market prospects, and here is a specific analysis:

Advantages and Opportunities

- Material Characteristics Advantages: Coroplast sheets possess numerous excellent characteristics such as light weight but high strength, impact resistance, corrosion resistance, moisture and mildew proof, and recyclability, enabling their widespread application in fields like packaging, advertising, and construction. This provides a broad application foundation for printed Coroplast sheets.

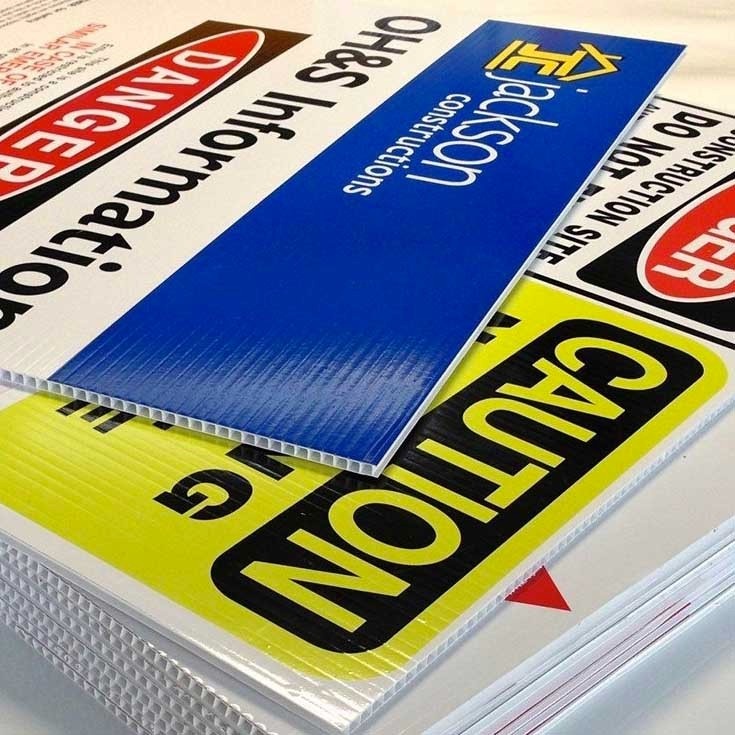

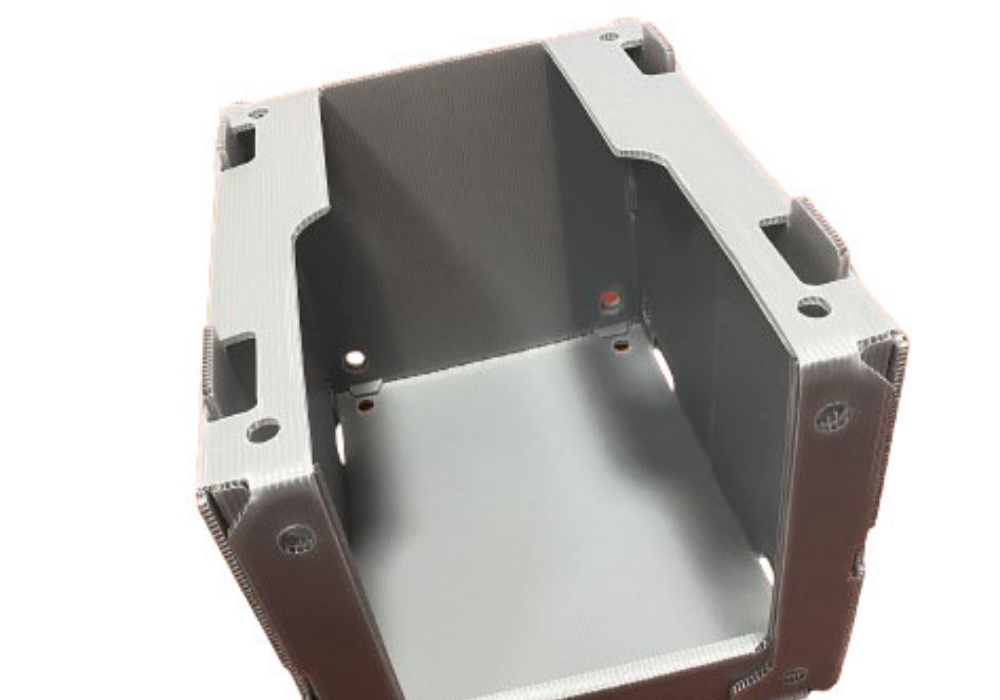

- Expanding Application Fields: In the packaging field, with the rapid development of e-commerce and logistics industries, the demand for high-quality and customized packaging materials is increasing. Printed Coroplast sheets can be used to make exquisite product packaging, enhancing the added value of products; in the advertising field, their strong printability allows for the production of colorful and eye-catching billboards and posters to attract consumers’ attention; in the construction field, they can be used as decorative materials or temporary enclosures.

- Enhanced Environmental Awareness: The global environmental protection awareness is continuously improving. As a recyclable material, Coroplast sheets are more favored in the market compared with traditional paper or wood materials. This will further promote the market demand for printed Coroplast sheets.

- Technological Development Impetus: The continuous progress of digital printing technologies, such as high-precision inkjet printing and UV printing, has improved the printing quality and efficiency of Coroplast sheets, reduced production costs, and been able to achieve more complex and delicate patterns and color effects, providing technical support for its market expansion.

Market Trends

- Obvious Demand Growth: According to statistics and forecasts by QY Research, the global Coroplast cardboard market sales reached a certain scale in 2023, and it is expected to reach a higher amount in 2030, with a positive compound annual growth rate (CAGR) (2024-2030). The Chinese market has changed relatively quickly in the past few years. In 2023, the market size was in the order of hundreds of millions of US dollars, accounting for a certain proportion of the global market. It is expected that the market size will reach in the order of hundreds of millions of US dollars in 2030, and the global proportion will change accordingly.

- Unbalanced Regional Development: At present, the Asia-Pacific region is the world’s largest consumer market, with a relatively high market share. It is expected to maintain a certain growth rate in the next few years. Meanwhile, North America and Europe are also important production and consumption regions, and their market shares are expected to continue to remain in the lead.

Challenges and Competition

- Fluctuation in Raw Material Prices: The main raw materials of Coroplast sheets are polypropylene and other plastics, and their prices are greatly affected by factors such as international crude oil prices and market supply and demand relations. The instability of raw material prices may increase the production cost and operational risk of enterprises.

- Intensified Market Competition: With the continuous development of the market, more and more enterprises are entering the field of printed Coroplast sheets, and the market competition is becoming increasingly fierce. Enterprises need to continuously improve product quality, reduce costs, strengthen brand building and marketing to stand out in the fierce market competition.

Product Details

| Parameter Item | Description |

|---|---|

| Material | Polypropylene (PP) plastic, a thermoplastic polymer known for its good mechanical properties, chemical resistance, and low moisture absorption. It is lightweight yet durable, making it suitable for various applications. |

| Thickness | Common thicknesses include 4mm, but other options may be available depending on the manufacturer and specific application requirements. |

| Sizes | Standard sizes are typically around 470x470mm, 484x504mm, and 1m x 1m, but custom sizes can also be ordered to meet specific project needs. |

| Weight | The weight of Coroplast sheets is relatively light due to their hollow structure. The exact weight depends on the size and thickness of the sheet, but generally, a 4mm thick sheet is lightweight and easy to handle during installation and transportation. |

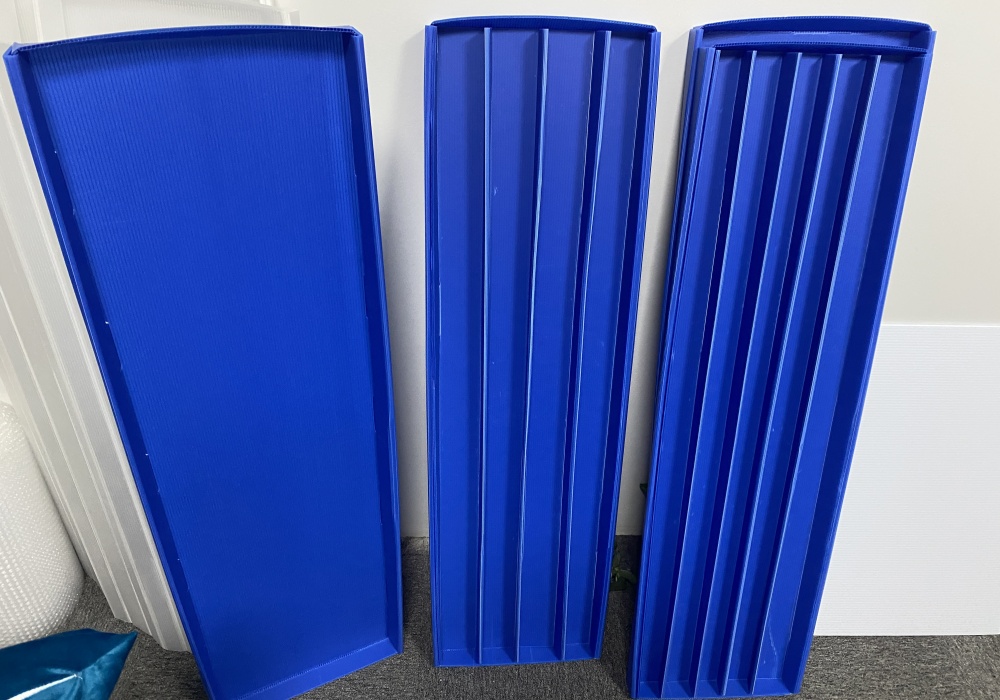

| Colors | Available in a wide range of colors, allowing for customization and matching of brand or design requirements. Common colors include white, black, blue, green, yellow, red, etc., but custom colors can also be produced upon request. |

| Printing Technology | Can be printed using various techniques such as screen printing, digital printing, and offset printing. Screen printing is suitable for simple designs and large quantities, while digital printing offers high-resolution and full-color capabilities for more complex and detailed graphics. Offset printing is ideal for large-scale production with consistent and accurate color reproduction. |

| Durability | Resistant to moisture, chemicals, and UV radiation, making it suitable for both indoor and outdoor use. It can withstand harsh weather conditions and maintain its color and structural integrity over time. |

| Recyclability | As a plastic material, Coroplast is recyclable, which makes it an environmentally friendly choice compared to some other materials used for signage and display purposes. |

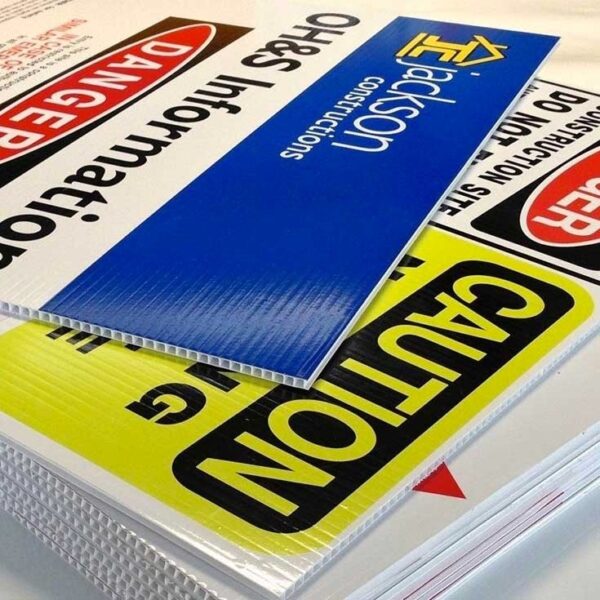

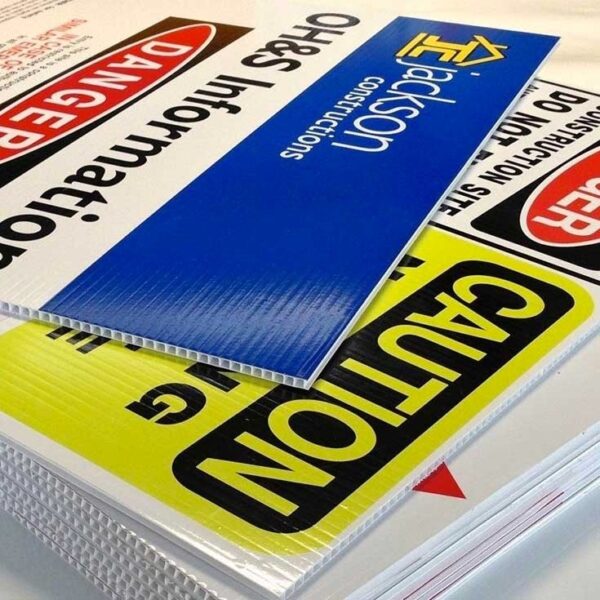

Product Gallery

What is the manufacturing process for Coroplast sheets with printing

The manufacturing process of Coroplast sheets with printing mainly includes the following steps:

- Material Preparation: Select high-quality polypropylene (PP) plastic particles as the main raw material to ensure the quality and performance of the material meet the requirements.

- Extrusion Forming: Melt the polypropylene particles through an extruder to form a uniform melt. Then, through a specific mold and cooling system, extrude the melt into Coroplast sheets with specific structures and sizes. During the extrusion process, it is necessary to control parameters such as temperature, pressure, and speed to ensure the quality and performance of the sheet.

- Surface Treatment: Perform surface treatment on the extruded Coroplast sheets to improve their print adaptability and adhesion. Common surface treatment methods include corona treatment and flame treatment. These methods can increase the roughness and polarity of the sheet surface, making it easier for ink to adhere to the sheet.

- Printing: Use appropriate printing techniques to print on the surface of Coroplast sheets. Common printing techniques include silk screen printing, digital printing, and offset printing.

- Drying and Curing: After printing is completed, it is necessary to dry and cure the printed products to ensure that the ink is fully dried and firmly attached to the sheet. Drying methods can be selected according to the type of ink and printing process, such as natural drying, hot air drying or ultraviolet drying.

- Post-Processing: According to specific application requirements, perform post-processing on the printed Coroplast sheets, such as cutting, trimming, bending, punching, welding, etc., to make products that meet the requirements.

- Quality Inspection and Packaging: Conduct comprehensive quality inspections on the finished products to check whether the printing quality, dimension accuracy, appearance, and other aspects meet the standard requirements. Inspect and package qualified products. They are usually protected by packaging materials such as plastic films, cardboard, or foam to prevent damage during transportation and storage.

Coroplast sheets with printing

certified by

Transform your space with vibrant Coroplast Sheets with Printing – where durability meets eye-catching appeal!

Specifications

Thickness: 0.5mm to 12mm

Size: 2400mm x 1200mm

Color: Customized

Hardness: rigid and sturdy

Density:0.92 to 0.98 grams per cubic

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon