Corona treated coroplast sheet is poised for a promising future in the market. With its enhanced durability, superior printability, and compliance with international safety standards, it is expected to see increased demand across various industries such as advertising, packaging, and construction. The growing emphasis on sustainable materials and advanced manufacturing technologies will further boost its market presence. As businesses and consumers alike prioritize quality and environmental responsibility, Corona treated coroplast sheet is well-positioned to capitalize on these trends, offering a reliable and versatile solution for diverse applications.

What is the manufacturing process for Corona treated coroplast sheet

The manufacturing process of Corona treated coroplast sheet is as follows. Firstly, the basic materials are selected and mixed to form a uniform raw material. Then, the raw material is extruded through a die to form a continuous sheet. During this process, precise temperature and pressure control is crucial to ensure the formation of an even sheet structure.

Next comes the corona treatment, which is a surface modification technique using a low-temperature corona discharge plasma. This treatment imparts changes in the properties of the sheet’s surface, such as improving its printability or creating specific surface textures. The sheet then goes through a cooling and shaping process, which may involve stretching or compressing it to achieve the desired thickness and shape.

Finally, the sheet is cut into the required dimensions and subjected to quality inspection to ensure it meets the specified standards before being packaged for shipment. Throughout the entire manufacturing process, strict quality control measures are implemented to guarantee the consistency and high quality of the Corona treated coroplast sheet.

Product Details

Here are some key parameters of Corona treated coroplast sheet presented in an English table format:

| Parameter | Description |

|---|---|

| Thickness | Ranges from 0.1 mm to 2.0 mm or customizable as per requirements. |

| Size | Standard sizes include 1220x2440mm, 1500x3000mm, and 1830x3000mm, with a tolerance of ±2mm. Custom sizes can be made according to the customer’s drawing or sample. |

| Color | Available in white, light blue, dark blue, yellow, green, gray, etc. |

| Material | Mainly composed of polypropylene (PP) and polyethylene (PE) |

| Surface Treatment | Corona treatment for improved surface energy and printability |

| Weight | Approximately 1.3-1.5kg/m² depending on the thickness and size |

| Fire Resistance Rating | Can be customized according to different standards like UL94 V0, UL94 V2, etc. |

| Tensile Strength | Generally around 20-30 N/mm² for the longitudinal direction and 15-25 N/mm² for the transverse direction. |

| Elongation at Break | About 10%-20% for both the longitudinal and transverse directions. |

| Working Temperature Range | From -20°C to 80°C. |

The above table provides an overview of the key parameters of Corona treated coroplast sheets, including their physical dimensions, material composition, surface treatment, weight, fire resistance rating, tensile strength, elongation at break, and working temperature range. These parameters are essential for understanding the performance and suitability of the sheets for various applications.

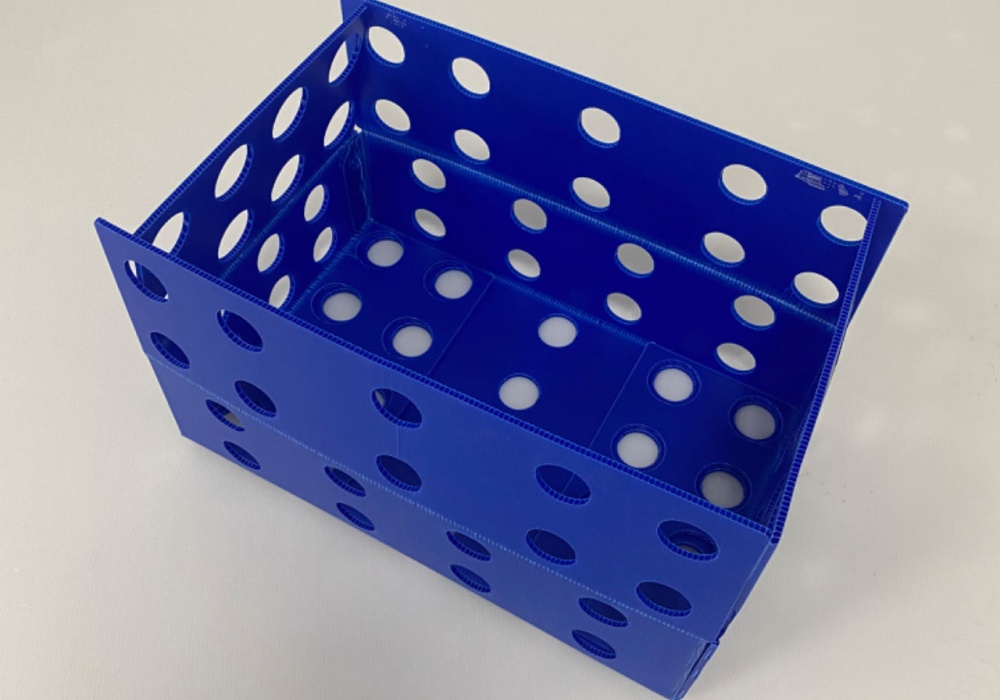

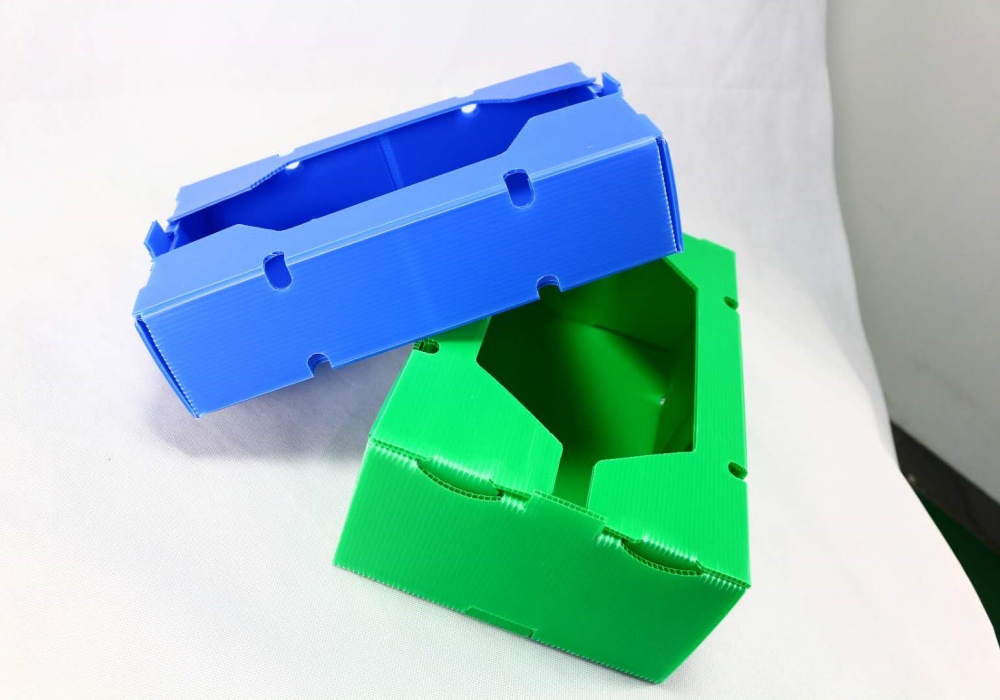

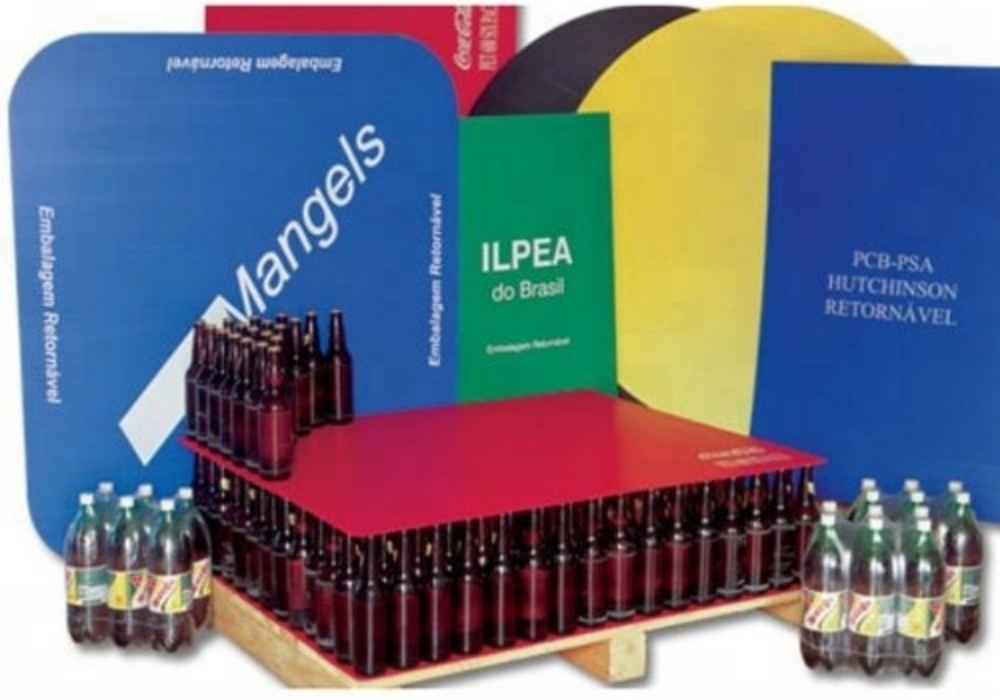

Product Gallery

Corona treated coroplast sheet is most popular in those industries

Corona treated coroplast sheets are most popular in the following industries:

Advertising and Signage Industry: These sheets are widely used for making high-quality signs, billboards, and display boards due to their excellent printability, weather resistance, and durability. The corona treatment ensures that the inks adhere well, resulting in vibrant and long-lasting graphics.

Packaging Industry: Corona treated coroplast sheets are preferred for packaging applications as they provide a good balance of strength, flexibility, and barrier properties. They can be used for protective packaging, labels, and tags.

Construction and Building Industry: These sheets are used in construction for temporary fencing, formwork, and screeding applications. Their durability and dimensional stability make them suitable for various on-site uses.

Automotive Industry: Corona treated coroplast sheets find applications in the automotive sector for protective coverings, interior parts, and decorative elements. Their lightweight nature and ease of fabrication make them a choice for automotive components.

Graphic Arts and Display Industry: Professionals in the graphic arts and display industry choose these sheets for creating eye-catching displays, exhibition stands, and point-of-sale materials. The corona treatment enhances the color reproduction and overall aesthetic appeal of the displays.

Event and Exhibition Industry: For event management and exhibition setups, these sheets are ideal for making directional signs, banners, and temporary structures. They offer easy installation and dismantling, making them convenient for short-term events.

Marine and Watercraft Industry: In the marine industry, these sheets are used for boat hull protection, dock fenders, and other watercraft components. Their resistance to moisture and chemicals makes them suitable for harsh aquatic environments.

Agriculture and Horticulture: In agriculture, these sheets are utilized for greenhouse coverings, plant protection, and irrigation channels. Their ability to withstand environmental factors helps in enhancing agricultural productivity.

In summary, Corona treated coroplast sheets have gained widespread popularity across multiple industries due to their versatile properties, ease of customization, and reliability in performance.

Corona treated coroplast sheet

certified by

Upgrade your space with our Corona Treated Coroplast Sheets – where durability meets elegance. Experience unmatched resilience and timeless beauty in one innovative solution.

Specifications

Thickness: 0.5mm to 12mm

Size: 2400mm x 1200mm

Color: Customized

Hardness: rigid and sturdy

Density:0.92 to 0.98 grams per cubic

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon