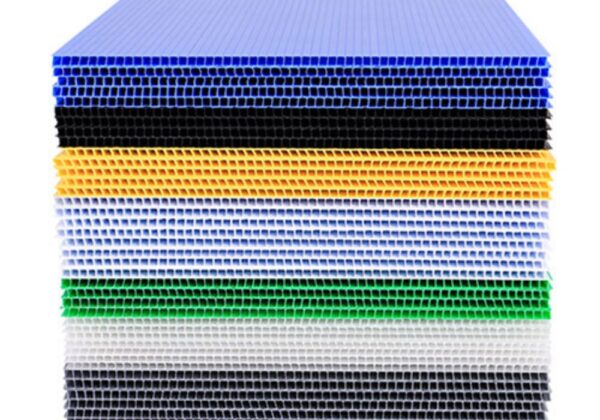

Regular corrugated plastic sheets are manufactured through a process that begins with the extrusion of polypropylene (PP) or other suitable thermoplastic materials. The molten plastic is formed into a flat sheet and then passed through a series of corrugating rollers, which impart a wavy pattern to one or both sides of the sheet. This creates the characteristic corrugated structure that provides enhanced strength and rigidity compared to flat sheets.

Regular corrugated plastic sheet Market outlook

Sustainability & Reusability: The market for regular corrugated plastic sheets benefits from the growing emphasis on sustainable practices, as these sheets are recyclable and reusable, reducing environmental impact and offering long-term cost savings, particularly in packaging applications.

Construction Sector Demand: With their durability, weather resistance, and ease of installation, corrugated plastic sheets see increased use in construction for temporary fencing, signage, and as structural components, driving demand as the industry seeks efficient materials.

Advertising & Display Applications: The versatility of corrugated plastic sheets in being easily cut, shaped, and printed upon caters to the advertising and retail display industries, where customizable and visually appealing materials are in high demand, fueling market growth.

Technological Advancements: Ongoing innovations in material science and manufacturing processes enhance the properties of corrugated plastic sheets, such as improved strength-to-weight ratios and better UV resistance, expanding their application scope and competitiveness.

Market Growth Projections: Despite challenges like raw material price volatility and competition, the overall market trend indicates steady growth due to the convergence of sustainability demands, industrial material needs, and continuous technological improvements.

Product Details

| Parameter | Description |

|---|---|

| Thickness | Measured in millimeters (mm), typically ranging from 1mm to 10mm or more, depending on the application and required strength. |

| Length and Width | Customizable based on specific needs, with standard sizes often available but can be cut to desired dimensions. |

| Corrugation Profile | Defined by the shape and size of the waves, including amplitude (height of the wave) and wavelength (distance between successive waves). |

| Material Type | Usually Polypropylene (PP), but can also be other thermoplastic materials like Polyethylene (PE) or PVC for specific properties. |

| Density | Mass per unit volume, affecting the weight and rigidity of the sheet; typically ranges from 0.91 to 0.95 grams per cubic centimeter for PP. |

| Tensile Strength | The maximum stress a material can withstand while being stretched or pulled before breaking, measured in Megapascals (MPa) or pounds per square inch (psi). |

| Flexural Modulus | Indicates the material’s resistance to deformation under load, measured in MPa or psi; higher values signify stiffer sheets. |

| Impact Resistance | Ability to absorb energy without fracturing when struck, often tested using Charpy or Izod impact tests. |

| Thermal Stability | The temperature range within which the material retains its structural integrity and performance characteristics, typically from -20°C to +80°C for PP. |

| Chemical Resistance | Compatibility with various chemicals and solvents, important for applications involving exposure to such substances. |

| UV Resistance | The capability to resist degradation when exposed to ultraviolet light, often enhanced by adding UV stabilizers during manufacturing. |

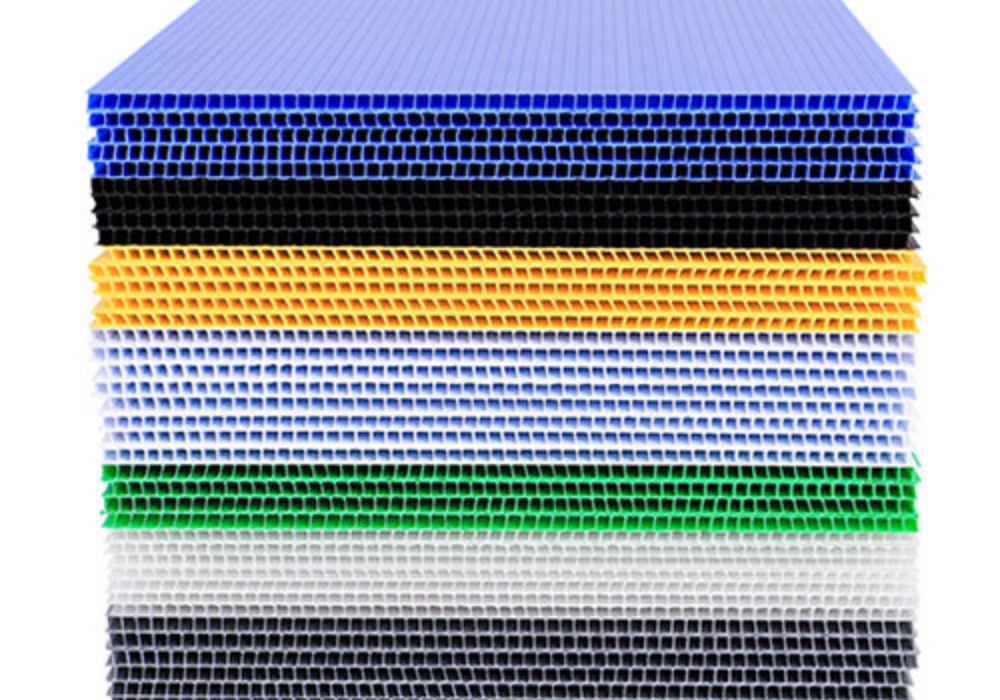

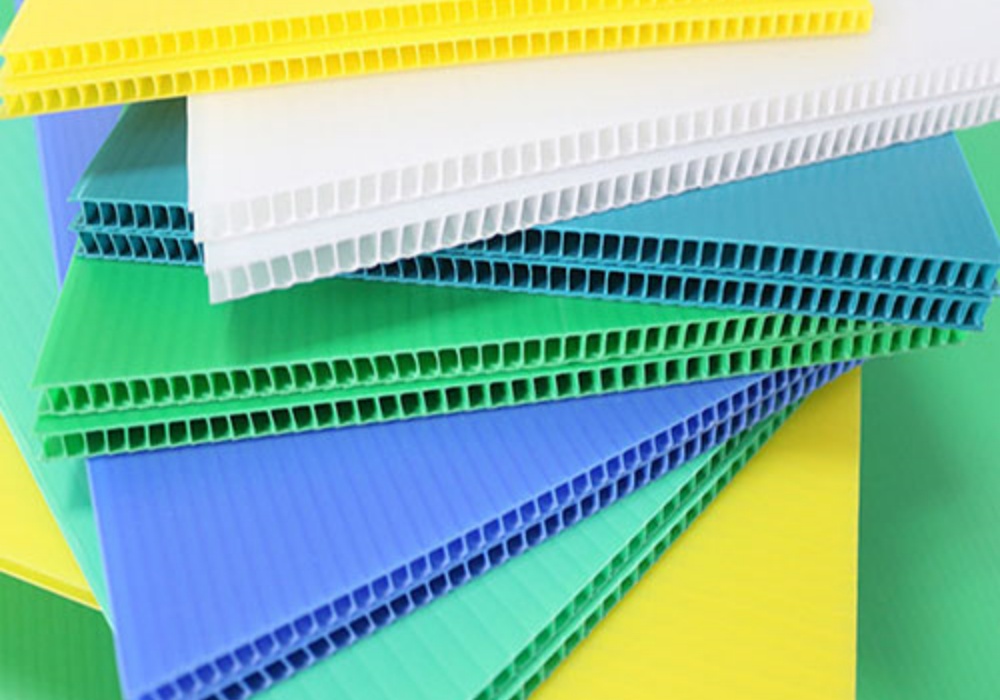

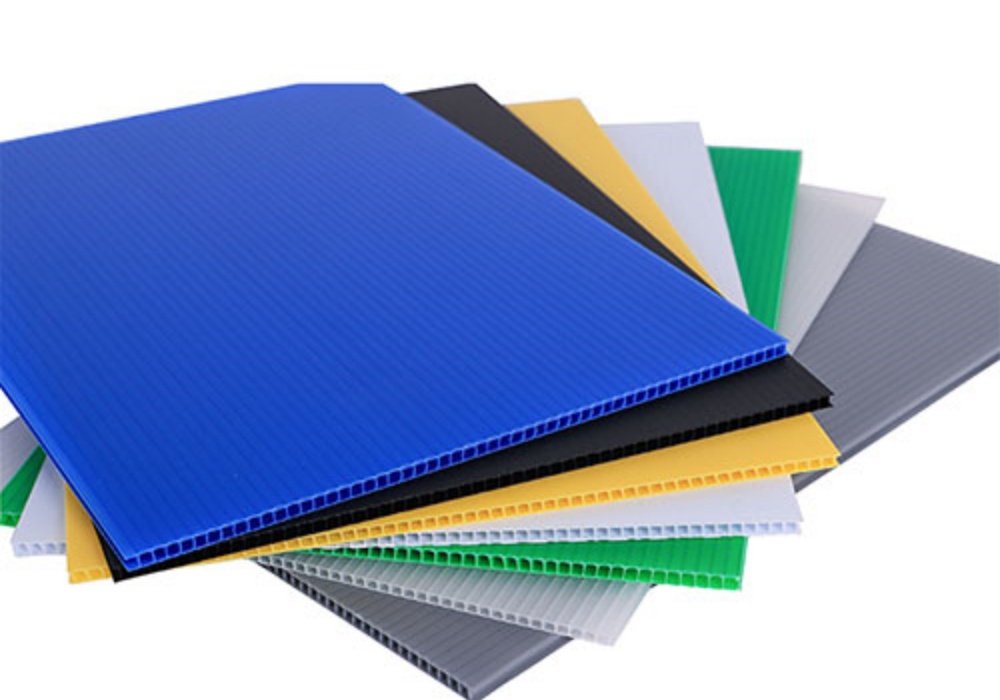

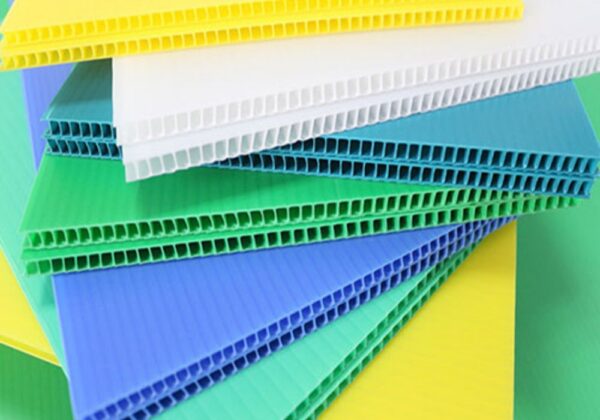

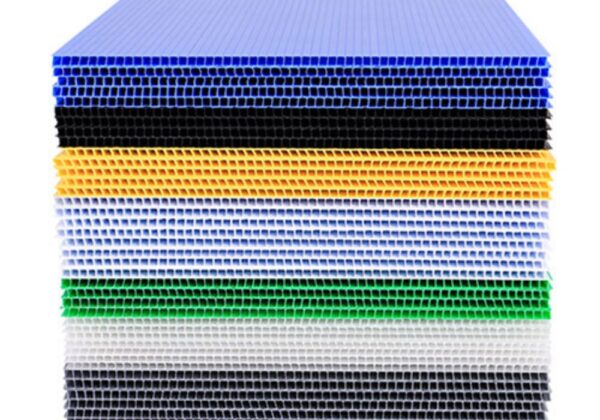

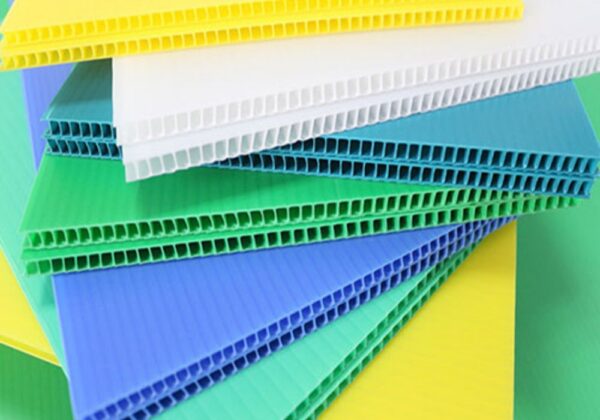

| Color Options | Available in a wide range of colors, achieved through the addition of pigments during production or post-production processes. |

| Surface Finish | Can be smooth, textured, matte, or glossy, depending on the manufacturing process and intended use. |

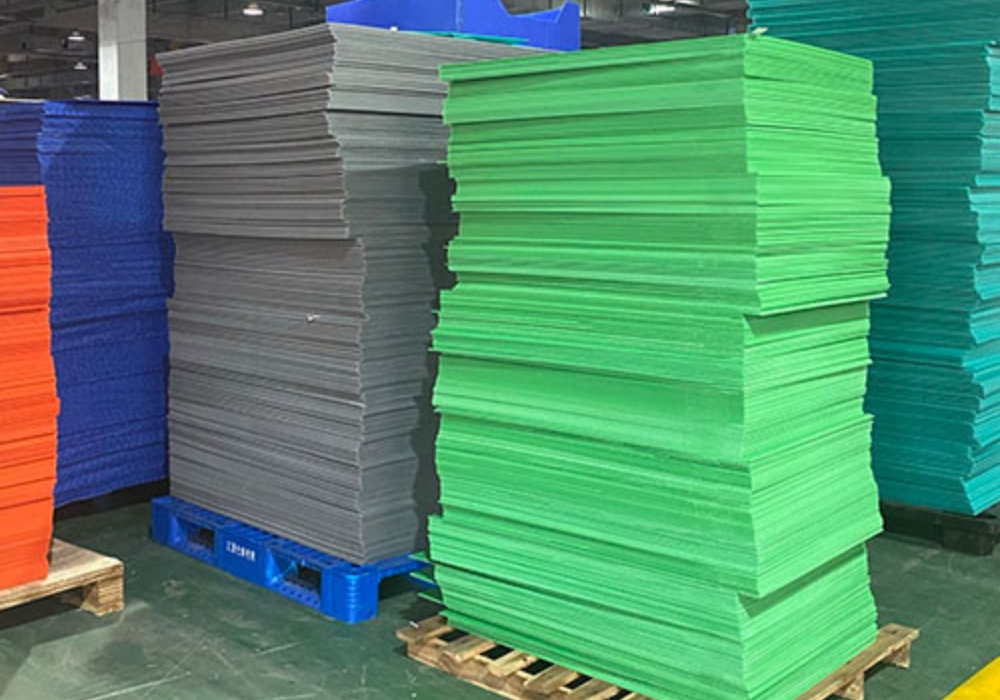

Product Gallery

Advantages of Regular corrugated plastic sheet

High Durability: They exhibit strong resistance to impact, making them suitable for heavy-duty applications and environments where other materials might easily get damaged.

Lightweight: Despite their robustness, these sheets are relatively light in weight, facilitating easy handling, installation, and transportation, which can reduce labor costs and increase efficiency.

Versatility: Available in a wide range of thicknesses, colors, and corrugation profiles, they can be tailored to meet diverse application requirements across various industries like packaging, construction, signage, and more.

Moisture Resistance: Impervious to water and many solvents, they do not warp, rot, or absorb moisture, ensuring longevity and maintaining performance even in humid or outdoor environments.

Eco-Friendly: Being recyclable and reusable, they contribute to sustainability efforts by reducing waste and promoting circular economy practices in comparison to single-use or non-recyclable materials.

Cost-Effective: Offering a balance between strength, functionality, and affordability, they provide a cost-efficient solution for projects without compromising on quality or performance.

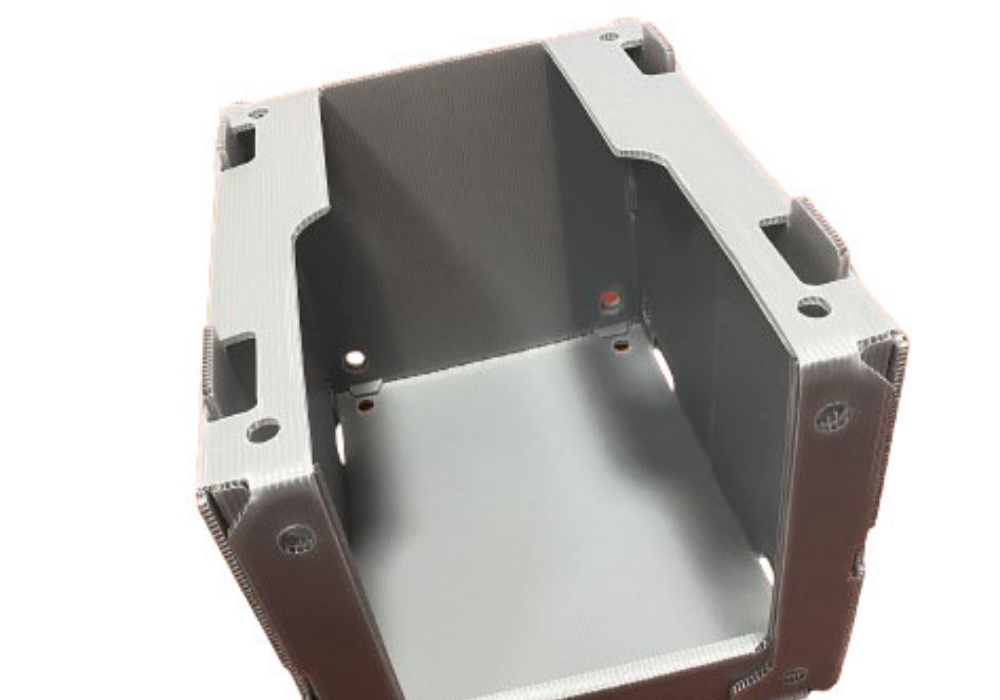

Ease of Fabrication: Can be easily cut, bent, welded, and formed into different shapes and sizes using simple tools and equipment, allowing for quick customization and adaptation to specific needs.

Excellent Strength-to-Weight Ratio: The unique corrugated design provides enhanced structural rigidity while keeping the material lightweight, making it ideal for applications requiring both strength and portability.

Chemical Compatibility: Depending on the material composition, they can withstand exposure to various chemicals, oils, and solvents, making them suitable for industrial and commercial applications where such resistance is crucial.

Aesthetic Appeal: With options for different colors and surface finishes, they can be used for visually appealing applications, including retail displays, exhibitions, and architectural elements, enhancing brand visibility and aesthetics.

Regular corrugated plastic sheet

certified by

Transform Your Projects with Our Regular Corrugated Plastic Sheets – The Perfect Blend of Durability, Versatility, and Style!

Specifications

Thickness: 0.5mm to 12mm

Size: 2400mm x 1200mm

Color: Customized

Hardness: rigid and sturdy

Density:0.92 to 0.98 grams per cubic

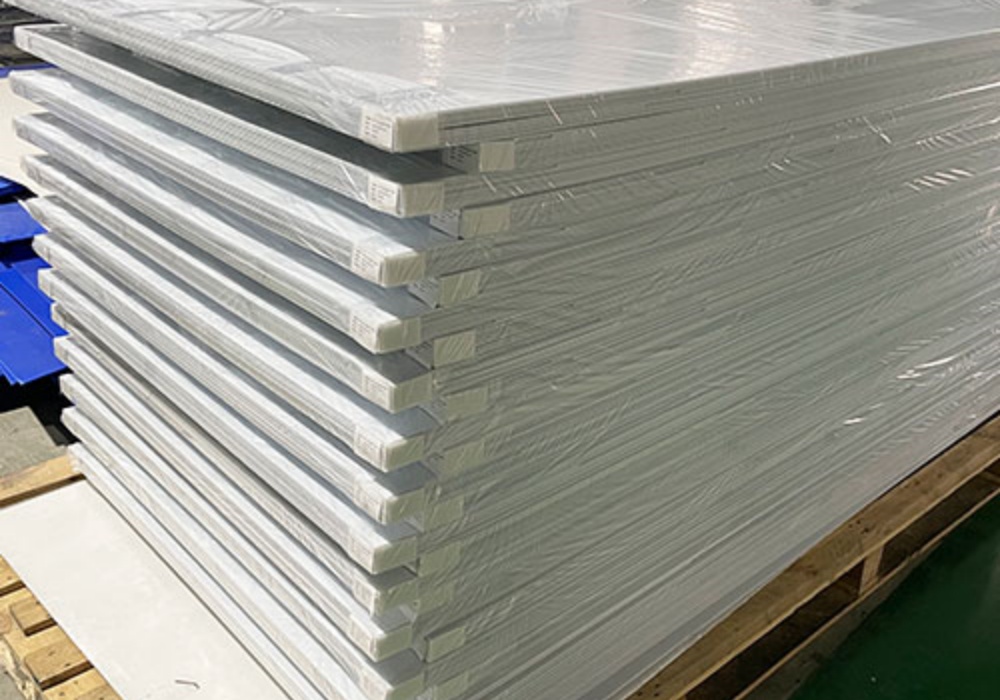

Packaging and delivery

Packaging Details: Plastic Bags

Port: Shanghai

Supply Ability:

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon